Integrating employees in digital production – digital Shopfloor Management

Less downtime and more safety with the dSFM solution

Are you tired of using handwritten notes for your shift planning or of manually entering the efficiency of your plants in Excel tables? What if the shop floor meeting gave you more freedom to optimize processes or coordinate with colleagues?

With a solution for digital shop floor management, the shop floor meeting becomes an innovation hub. Because one thing is certain: only with high process quality can you maintain the performance level of your machines and positively develop your overall equipment efficiency – and simultaneously give all employees a voice.

Optimize your Shopfloor Management

During the classic morning shop floor meeting, production problems and tasks are usually continuously discussed, analyzed, and optimized in the long term. These topics include occupational safety, quality, productivity, and control measures. In most production companies, shop floor management based on the lean management approach has established itself as a very effective tool for continuous improvement.

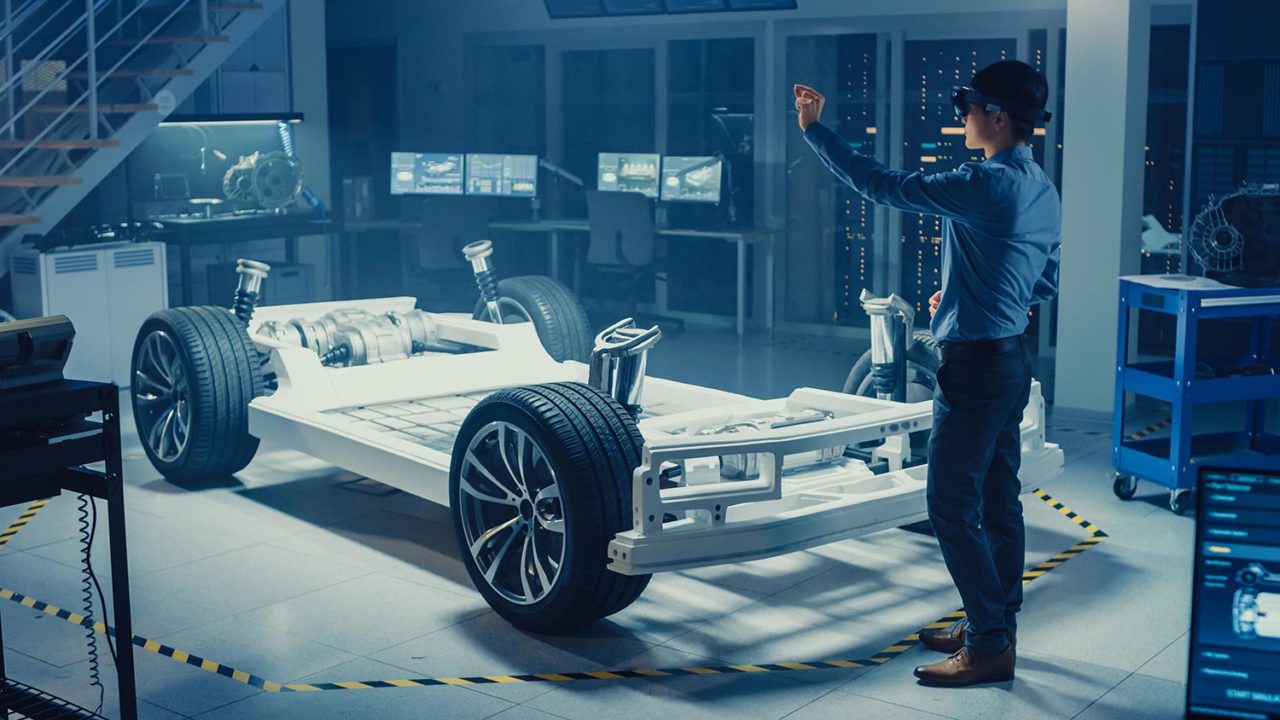

The use of our digital Shopfloor Management (dSFM) software opens up new opportunities to further optimize these existing processes in the age of Industry 4.0, while still maintaining the basic idea of lean management – continuity.

With the help of digital Shopfloor Management, information from production (MES), employees (HR), shift events (malfunctions, quality), measures, and much more is continuously recorded, historicized, and made available globally in real time.

Our Germanedge solution for digital Shopfloor Management

Germanedge offers sophisticated software for digital shift management, suitable for any manufacturing company.

Your advantages at a glance

Continuous digitization through automated interfaces

With Germanedge’s dSFM, you can achieve end-to-end digitization of your shop floor management for demonstrably more effective collaboration and more efficient processes in your company.

The solution is the linchpin for the entire shop floor operation and serves as a so-called single source of truth: All relevant information is either enriched by employees or collected, aggregated, and archived in real time through automated interfaces to other IT systems, such as machine data. Information from production is processed in such a way that the dSFM can be used to assess why, for example, a system failure occurred and what measures need to be taken.

Better communication thanks to dSFM

The cross-plant and cross-company exchange of information is always based on current data – miscommunication or even the initiation of wrong measures is thus largely prevented. This ensures better communication and more efficient processes, especially in the analysis of causes and recommendations for measures. Ultimately, this results in a sustainable improvement in overall equipment efficiency (OEE) and drastically reduces downtime.

Efficient change management process

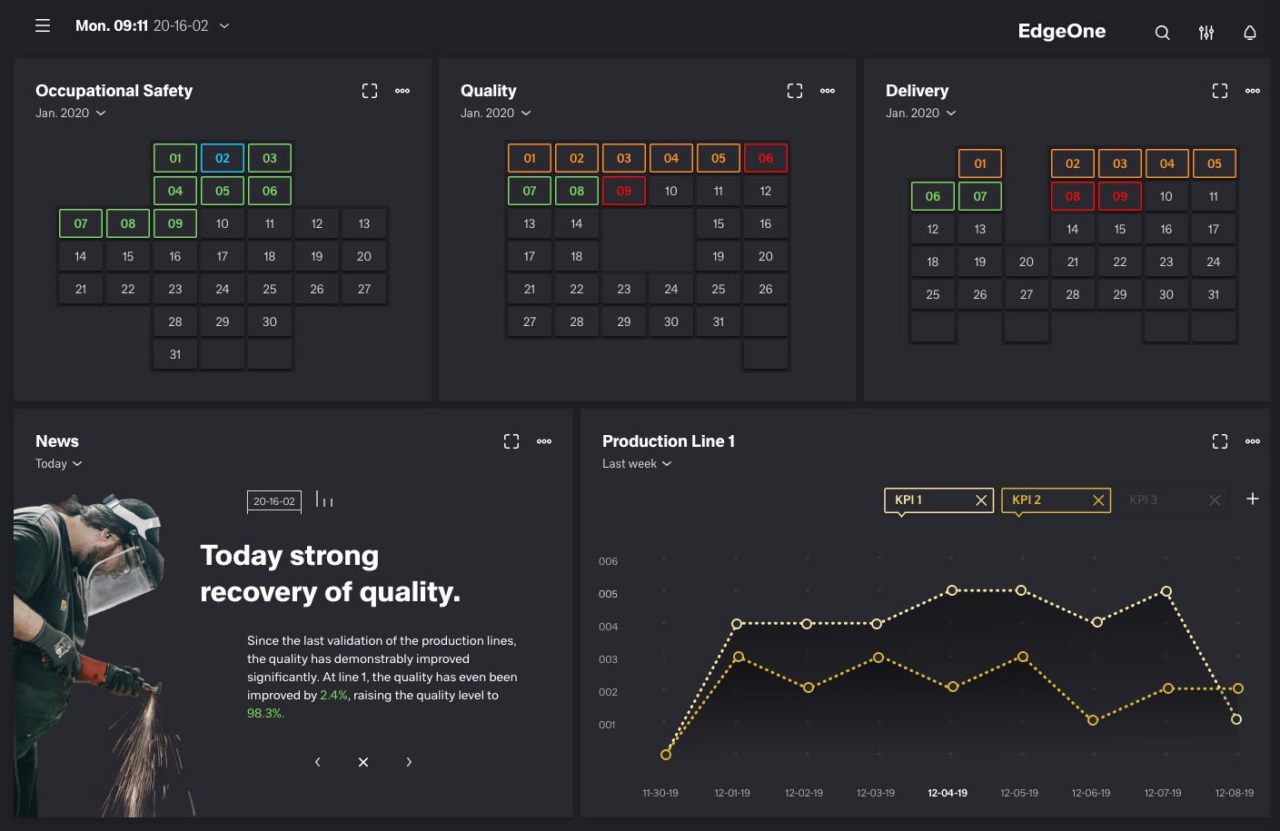

Our solution for your digital Shopfloor Management offers concrete added value: with the help of customizable KPIs, deviations in capacity utilization and damage can be recognized early on, which can be quickly remedied. This not only increases the OEE, but also gives all employees a transparent overview of production through standardized processes.

Operating the software requires little training – and involves all colleagues. The local voice of each employee is the basis for a global problem-solving and continuous improvement process. This makes correlations visible and allows solutions to be derived quickly and effectively. With our digital solution for shop floor management, Germanedge supports you in sustainably improving overall equipment efficiency (OEE).

This way, you increase your company’s level of maturity in digitalization and simultaneously optimize your production capacity utilization through transparency. The software provides up-to-date, comprehensive information in a graphically understandable format and can generate trends and forecasts based on historical data.

Integrated in the Germanedge platform Edge.One

Our digital solution for Shopfloor Management (dSFM) is integrated in the Germanedge platform for MES and MOM, Edge.One. The modern and intuitive user interface makes the solution clear and easy to use. In addition, other Germanedge solutions such as the MES from GEFASOFT, Lega Sapient, or other third-party software can be integrated into this PaaS. This results in a maximum depth of data, enabling analyses all the way to Big and Smart Data Analytics.

Get in touch!

Would you like to know more about our solutions? Then please write me using the contact form. I will get back to you as soon as possible.

Christoph Schiffer

Sales Team Germanedge