Ready for the future of digital production with Edge.One

Edge.One is the platform as a service solution for your MES and MOM processes

The future of digital production does not consist of various isolated solutions and the resulting separate data streams and work areas, but from an intelligent, integrated flow of all your data, resources, and processes.

In order to break down existing silos and create an ecosystem for all MES and MOM processes, an intelligent data hub is needed. The shop floor must be connected to the business level, the supply chain to quality control management, and non-conformance management – ideally supported by integrated non-conformance management software – to advanced product quality planning. Only in this way can production efficiency be sustainably increased and the power of smart data be generated from big data.

A platform that makes all this possible yet is still intuitive to use is by no means a pipe dream.

With Edge.One, we offer a platform as a service (PaaS) solution that enables you to take full advantage of all the benefits that cloud, automation, and IIoT have to offer. Edge.One makes it possible to collaborate in an orchestrated, collaborative, intelligent way across all production disciplines.

Launch into the future with the Edge.One MES / MOM platform

Anyone who is already thinking about the future of production, establishing a comprehensive digitalization strategy, and looking for integrated solutions cannot fail to come across the concept of a production platform. The future is not only in the cloud – it is also a platform.

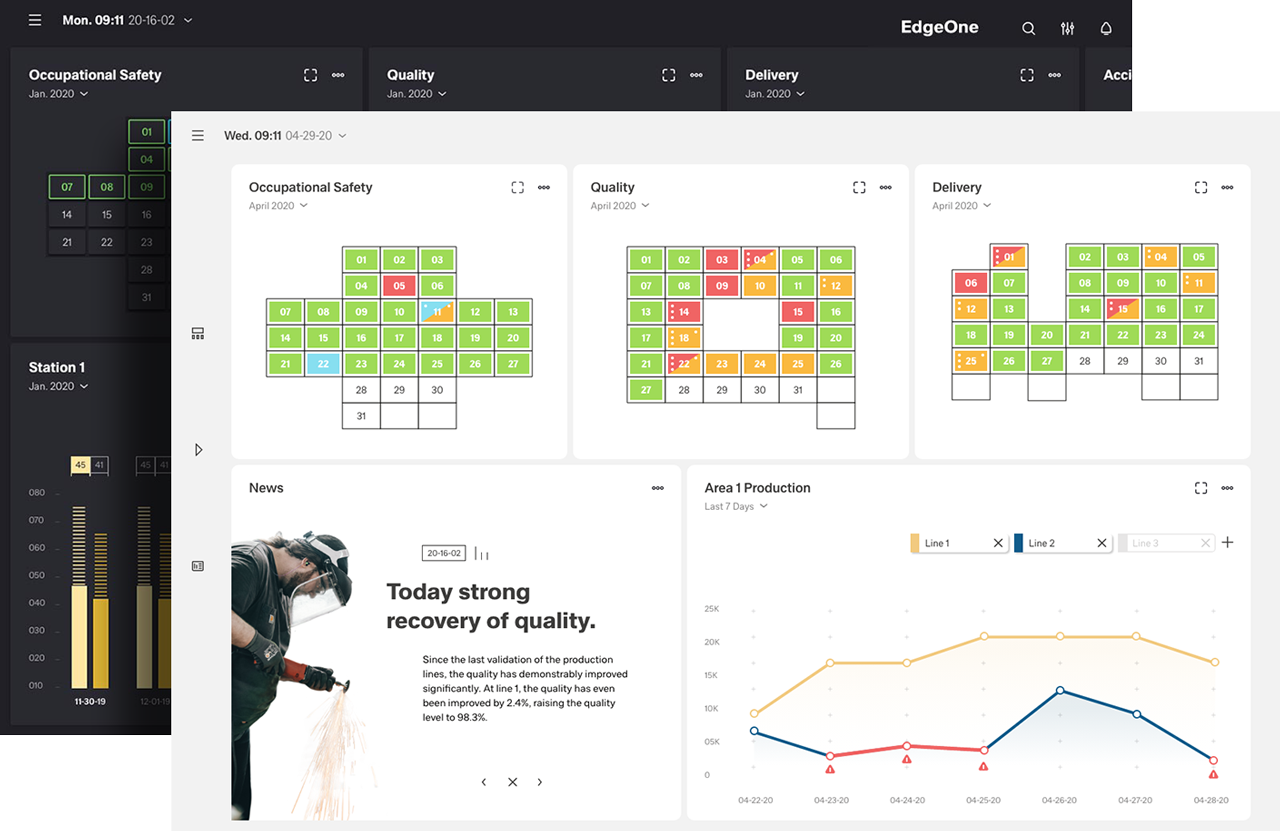

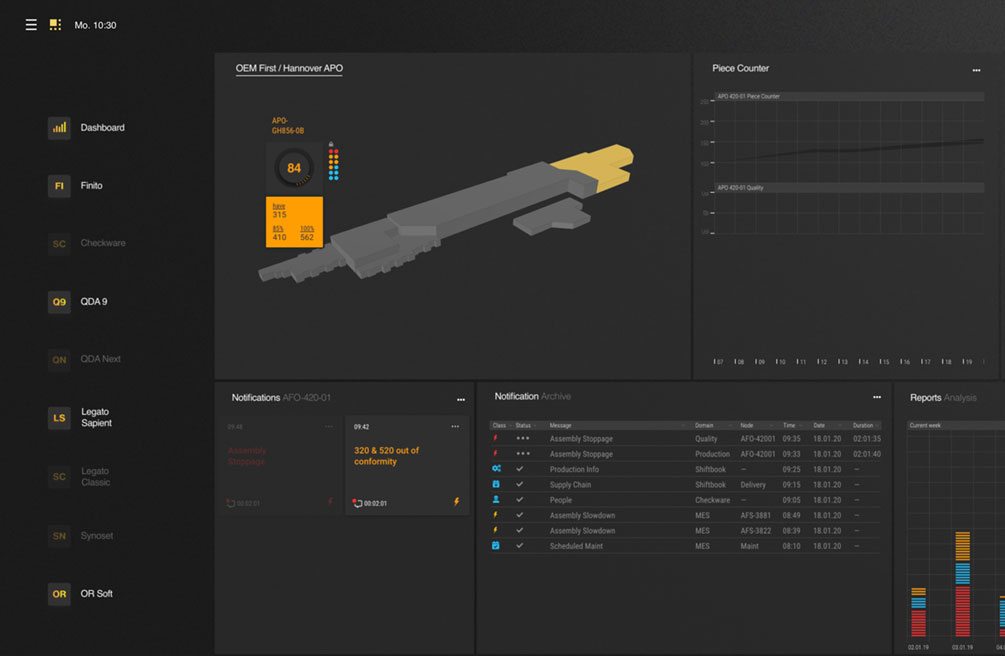

With Edge.One, we at Germanedge have developed a completely new MES and MOM PaaS that is based on an open enterprise architecture. In Edge.One, all offers of the Germanedge product providers GEFASOFT, New Solutions, QDA SOLUTIONS, and ORSOFT are integrated in a unified production workplace. This offers a wide range and depth of information. In addition, our state-of-the-art user interface and guidance based on our “Inspire” design system makes the use of new platform applications intuitive and highly efficient.

Our platform design system "Inspire"

Our Edge.One platform offers a unique design system called “Inspire”, which focuses on intuitive use of the platform by production staff. This user-centric approach puts the human factor at the forefront of the application of software in the production environment: after all, it is the employee who brings the smart factory to life. Accordingly, the “Inspire” design system was a fundamental factor for Germanedge in the development of Edge.One. “Inspire” combines all components within Edge.One: one design system for all solutions integrated in Edge.One.

The design system is based on two pillars:

- the UI design with a focus on how the solutions are presented within Edge.One

- the UX design, which allows the user to interact intuitively with the Edge.One platform and all integrated solutions

Edge.One’s “Inspire” design system creates a state-of-the-art user interface that makes it easy, efficient and user-friendly to exploit the possibilities of a smart, intelligently networked factory. To use Edge.One, our clients only need to make minimal input to get the desired output in the best possible fit-for-purpose data view.

Fully integrated platform solution with business analytics & the cloud

Edge.One has a service-centric architecture: our platform for your production IT is individually configurable and offers you 360-degree access to all Germanedge solutions – fully integrated in a uniform user interface and with holistic data flows.

Our MES and MOM platform is rounded off by the combination of business analytics as well as smart data and AI to optimize production activities from process planning to final production. All offers available there, be they Germanedge solutions or third-party software, are available to you in the cloud. This means Edge.One can be implemented quickly and from any location.

Bring your digital production processes to the next level!

With our production platform for MES and MOM, you can meet your requirements for production efficiency, quality, transparency, and reduced production times – all in a single environment with Edge.One.

The advantages of Edge.One at a glance

dSFM as Germanedge solution in Edge.One

As one of the first cloud-based Germanedge solutions, dSFM, digital Shop Floor Management, shopfloor-software, is available in Edge.One. With the help of the dSFM software, information from production (MES), employees (HR), shift events (malfunction, quality), measures, and much more is continuously recorded, historicized, and is available globally in real time.

In Edge.One you can easily connect this solution with other modules. You can, for example, combine data from your shop floor with a quality management module, in order to combine information about product defects and machine incidents and subsequently take preventive action against them. In addition, the platform structure allows you to combine dSFM with third-party data in our analysis solution, thereby reducing complexity and generating smart data.

Fit for the future of production

- Circular Economy

- Cloud Computing in manufacturing

- Connected Worker

- Digital Twin

- IoT in Manufacturing Operations

- Manufacturing Network Design

- MOM Application Suite

- OEE: Overall Equipment Effectiveness

- Prescriptive Analytics

- Smart Factory

- Solution-Centric Supply Chain

- Supplier Quality

- Supply Chain Convergence

- Supply Planning

- Track and Trace

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge