Risk Radar Software

Recognize problems early with Risk Radar management

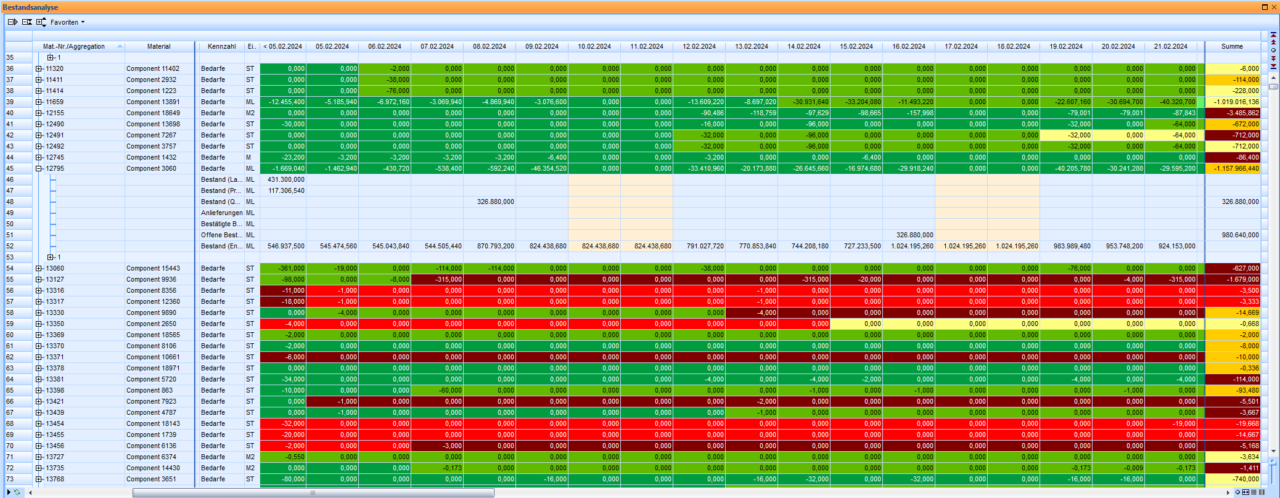

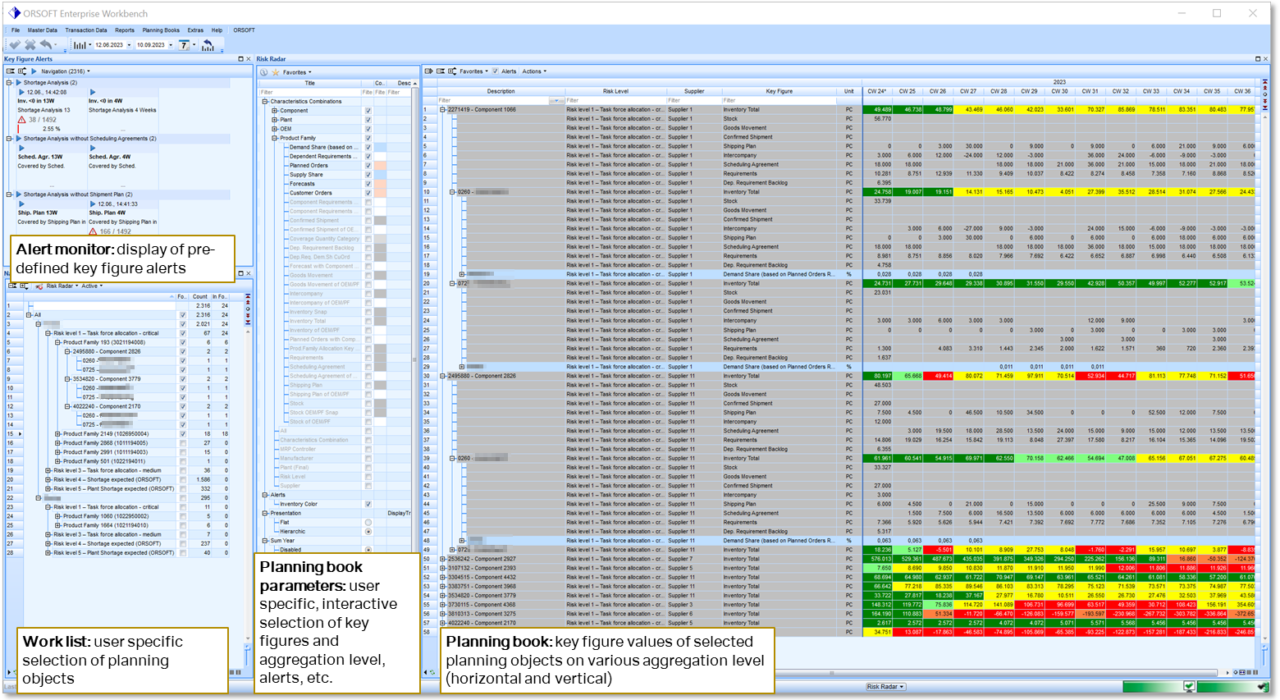

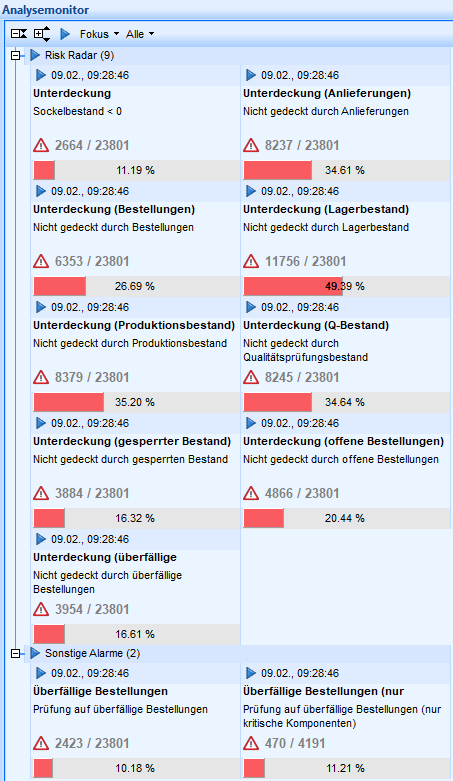

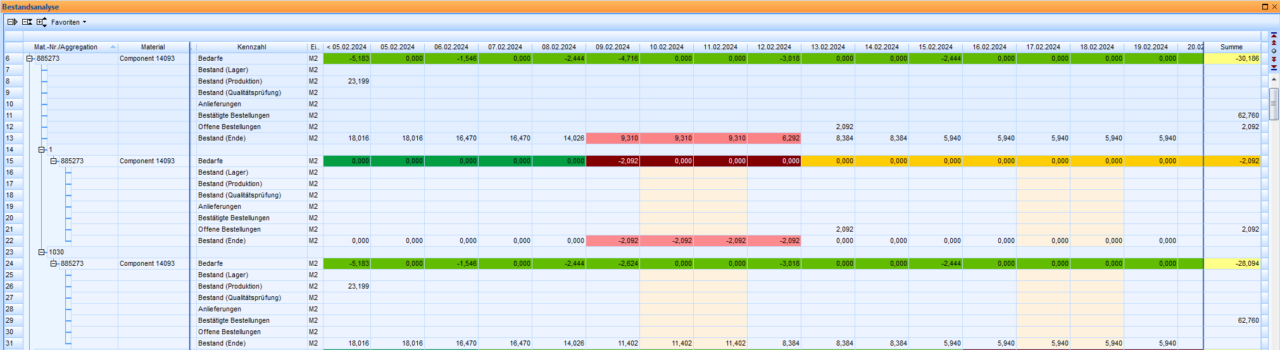

With our Risk Radar software, you can identify shortfalls in the entire cross-plant logistics chain completely automatically. The tool graphically visualizes the entire logistics chain and its effects. This allows you to solve problems before they even occur, which automatically leads to better delivery reliability. Plus: A key component is the direct linking of suppliers of a purchased part and the associated customers across the entire production structure.

Thanks to the rapid implementation based on the ERP system, the focus on relevant materials and the facilitation of cooperative optimization measures, the Risk Radar increases the service level. It also increases analysis efficiency and delivery performance while minimizing contractual penalties.

Advantages of our Risk Radar Software

Functions of our Risk Radar Software

Automatic decomposition of large production models

Our Risk Radar software automatically breaks down large production models into relevant, lean logistics chains from the supplier to the end customer. This is important because the actual advantages of just-in-time logistics (e.g. reduction of storage capacities and storage costs as well as optimization of throughput times in production) no longer function smoothly in times of disruptive supply chains.

Using Risk Radar Management, we bring together all parts of production – supplier, components, sales material and customer – to model a lean, continuous supply chain.

Identification of potential bottlenecks

Germanedge’s Risk Radar Assessment Tool ensures that potential bottlenecks and their impact on the end customer of corresponding sales materials are identified. The result: a central, holistic view of the logistics chain.

Decentralized information silos along the entire logistics chain of a tier-n manufacturer are also broken down with a central instance.

Automatic risk classification from low to critical

Based on defined scarcity parameters, each component in production is assigned a risk level. This prevents bottlenecks and performs an analysis of demand and supply of components in order to automatically categorize components according to their shortage risk.

Find out more!

OnDemand-Webinar on the topic of Risk Radar Software - ONLY IN GERMAN!

Das Webinar bieteten wir aktuell als OnDemand-Webinar an. Sie sollten sich anmelden, wenn Sie …

- Ihr Service Level um bis zu 3% erhöhen wollen

- die Analyseeffizienz um 50-80% steigern wollen

- durch Vergleich des Lieferplans die Lieferperformance um 2% steigern möchten

- Vertragsstrafen reduzieren und vermeiden wollen

Who benefits from our Risk Radar Software?

Advantages for sales managers

Your company’s ability to deliver and the corresponding customer satisfaction is one of the most important criteria for a production company. As a sales manager, you must adapt sales strategies according to production and delivery capability and communicate with customers. Using Risk Radar Management, you can quickly identify delivery bottlenecks and take countermeasures to improve delivery reliability and increase customer satisfaction.

Advantages for supply chain managers

As the person responsible for supply chain management, you need an overall view of logistics processes. It is essential that you maximize the efficiency and reliability of the supply chain and identify bottlenecks. With our Risk Radar sssessment Tool, you can reliably identify weak points because our software displays them transparently. The tool also enables you to immediately initiate proactive measures to avoid bottlenecks.

Advantages for planning and production managers

To avoid production downtimes, it is essential to ensure the constant availability of required materials. With our Risk Radar software, you as a planning and production manager can adjust the production plan at an early stage to avoid risks such as production downtime or delivery difficulties and draw up a corresponding schedule.

Advantages for purchasing managers

As a purchasing manager, you must ensure that critical materials and components are always available despite volatile markets and take appropriate measures to ensure this. With the Germanedge Risk Radar software, you can quickly identify risk materials in order to maintain an overview and procure appropriate materials in good time.

Wide range of options for integrating our Risk Radar software

Our Risk Radar Assessment Tool is designed as an application of our PaaS platform Edge.One. The modern framework acts as a central digital hub for all Germanedge and third-party applications. The goal: nothing less than the digital factory.

In order to integrate the Risk Radar Management Tool, the customer needs to know all the factors influencing material stocks. Ideally, these are available in the ERP system. The software offers a standard model for analyzing inventory situations and is open for adaptation to the customer-specific classification of data.

Germanedge offers the following integration options:

- Direct SAP integration for reading SAP data: Exchange of relevant master data and transaction data

- Certified SAP interface for SAP ERP and SAP S/4HANA

- High-performance bidirectional SAP interface

The consulting team is also available to set up Risk Radar to fit your SAP customizing.

Have we sparked your interest in Risk Radar? Here's how to proceed step by step:

- Get in touch with us

- Germanedge shows you the software in a live demo

- Our expert discusses requirements and technical integration with you

- We support you with integration and launch

What is Risk Radar Software?

Definition

The Risk Radar analyzes and classifies data using algorithms to profile and monitor your supply network. The most important functions of the Risk Radar are

-

- Systematic identification: Automatic detection of potential risks in the supply chain

- Visual analysis: Graphical representation of these and their impact on company processes

- Proactive measures: Risk minimization through early intervention before they have a negative impact

- Improving delivery reliability: Supports companies in ensuring a continuous supply and compliance with delivery obligations

- Increasing resilience: Increases resilience to supply chain disruptions through proactive risk identification and management.

- Decision support: Provides decision-makers with important information for risk assessment and management.

Which areas does (Supply Chain) Risk Radar affect?

-

- Supply chain planning and control: Optimization of production plans and inventories based on risk analyses.

- Procurement: Identification of risks in the procurement of materials and components as well as in the selection and evaluation of suppliers.

- Production: Early detection of production risks, including material shortages or production bottlenecks.

- Customer relations: Identification of risks relating to customer satisfaction and delivery reliability in order to avoid risk costs.

- Supplier management: Monitoring and management of supplier risks, including the evaluation of supplier performance.

How does Risk Radar software work?

-

- Data collection: Collects data from internal ERP systems (e.g. SAP) and, if necessary, external sources.

- Data analysis: Uses algorithms to identify and analyze potential risks in the supply chain.

- Automatic identification: Automatically identifies shortfalls and other risks in the supply chain.

- Risk assessment: Categorizes identified risks according to their urgency and potential impact.

- Visualization: Graphically displays risks and their impact, often in dashboards or as reports.

- Alerting: Proactively notifies users of critical risks or shortfalls.

- Recommendations for action: Provides suggestions for countermeasures based on the analysis.

Who is a Risk Radar Tool suitable for?

-

- Supply Chain Manager: For monitoring and optimizing the supply chain.

- Risk manager: For identifying and assessing risks in various business areas.

- Production manager: For the early identification of production risks and bottlenecks.

- Purchasing manager: For the assessment and management of supplier risks.

- Sales manager: To ensure product availability and customer satisfaction.

Get in touch!

Do you have specific questions about the Risk Radar software? Please write to us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales at Germanedge