Hidden OEE treasure: Why quality is the biggest profit booster

OEE – Better efficiency. Higher quality.

Your production is under intense pressure every day: ever shorter product cycles, more spontaneous delivery dates, and increasing quality demands characterize the business.

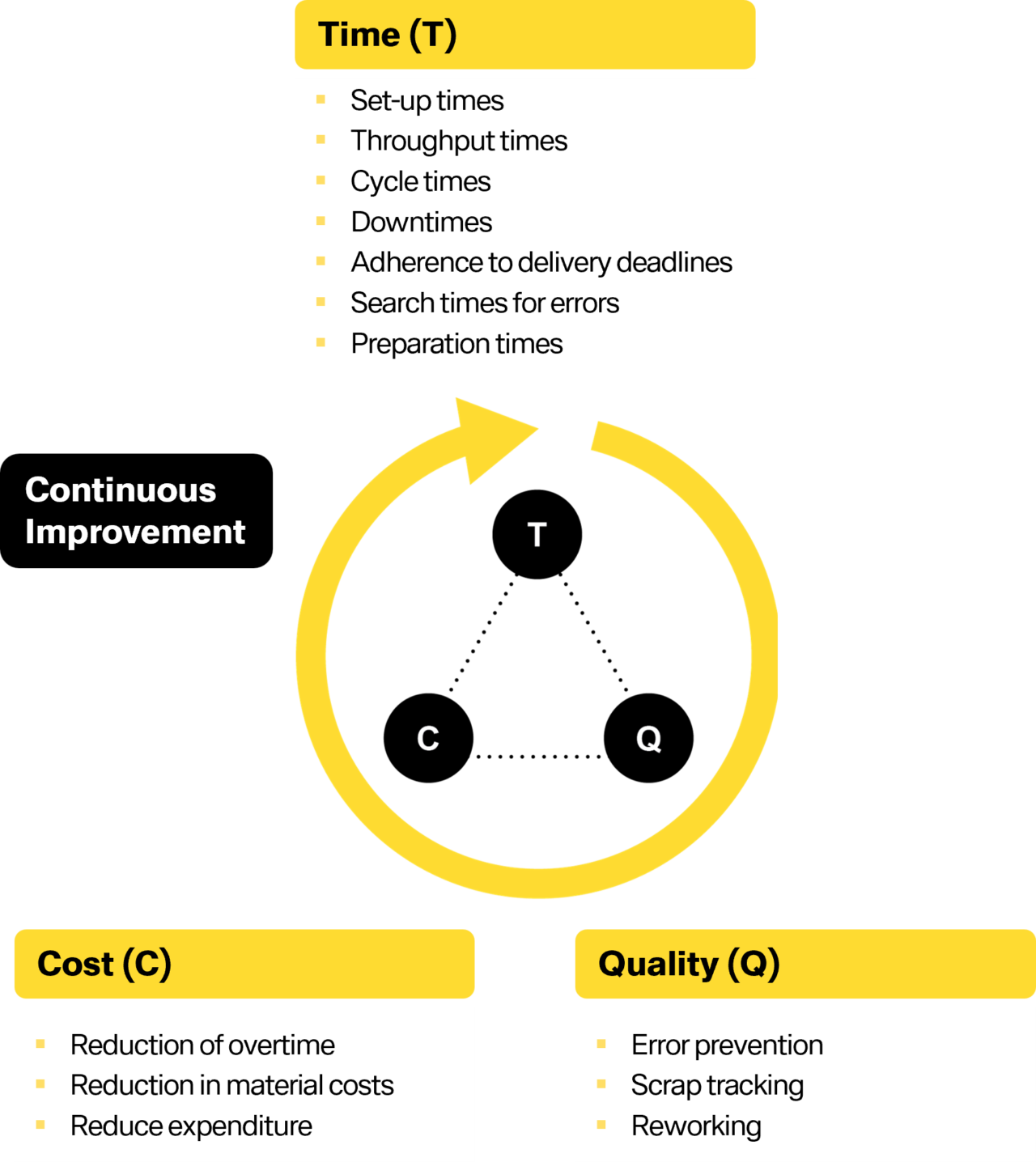

At the same time, cost pressures (e.g., skilled labor, energy) and sustainability requirements are constantly increasing. Production managers thus find themselves in the notorious “Bermuda Triangle” of quality, time, and costs—sometimes conflicting requirements that nevertheless must be balanced on a daily basis.

Continuous improvement has become a matter of survival. But where exactly is the greatest leverage for improvement?

OEE as a key performance indicator:

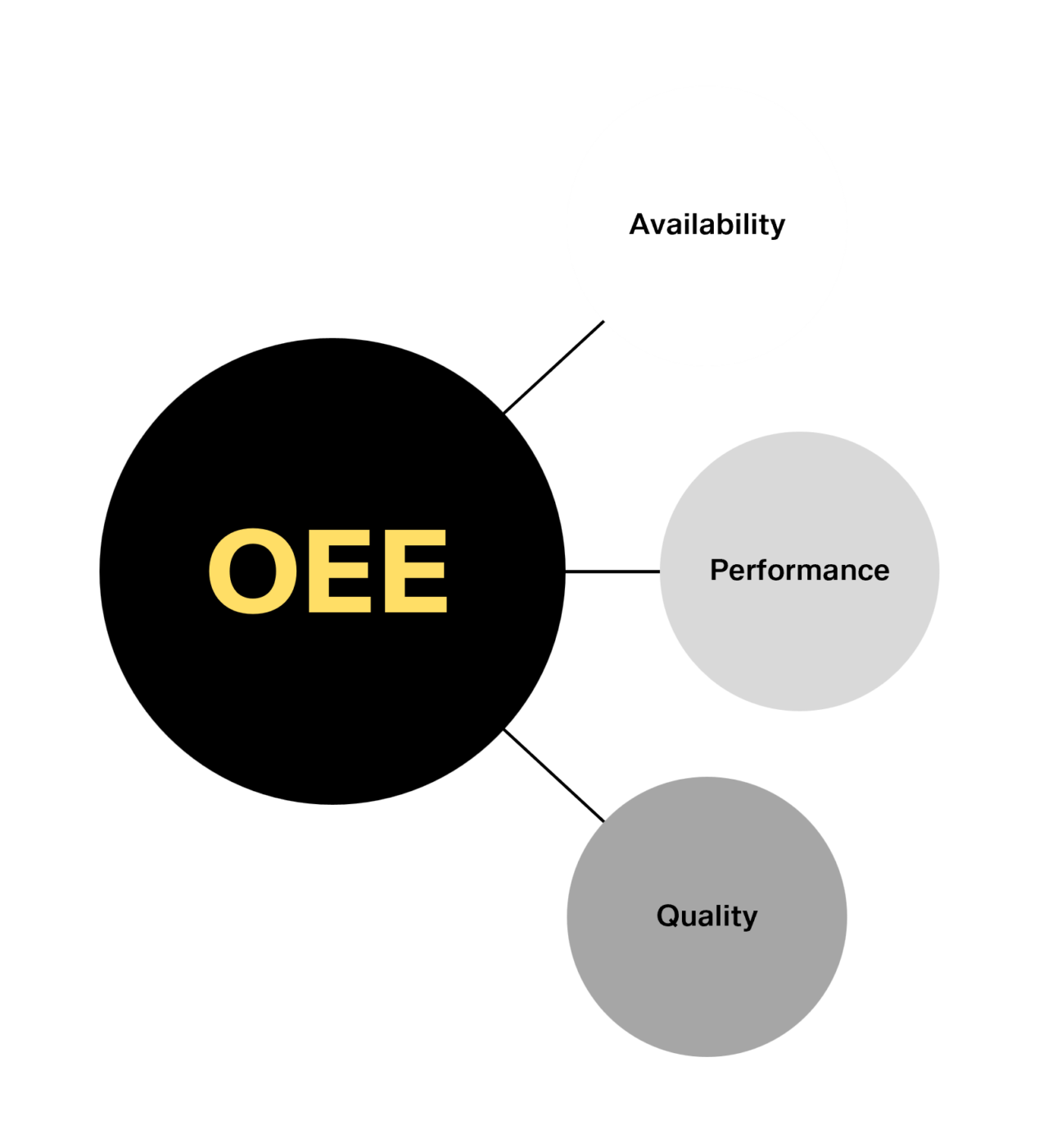

This is where Overall Equipment Effectiveness (OEE) comes into play. This key performance indicator has proven itself in practice for over 30 years and remains one of the most important KPIs in manufacturing for evaluating plant productivity, even in the age of Industry 4.0.

OEE shows at a glance how efficiently a plant is producing – based on availability, performance, and quality. This creates transparency: companies can immediately identify bottlenecks, downtime, and inefficient processes – and take data-based countermeasures.

OEE serves as the basis for continuous improvement – OEE data can be used to identify specific areas where hidden losses occur.

Quality – the decisive factor in the OEE

Quality is not just a component of OEE—it is the critical point where efficiency, customer satisfaction, and profitability converge. In practice, poor quality has multiple negative effects:

- Rejects and rework cost time and materials, reduce actual added value, and obscure the efficiency of your processes.

- Undetected quality problems lead to defective products, customer complaints, or recalls—with a direct impact on brand image and delivery reliability.

- Quality defects prolong testing times, complicate stable process flows, and lead to additional coordination and documentation efforts in quality assurance.

In other words, a single faulty component can devalue an entire shift’s output. Those who systematically measure quality and evaluate it in real time can intervene early, eliminate causes, and build process stability. And this is exactly where OEE comes in: it links quality losses directly to production output and availability, thus creating a complete picture of actual efficiency. Germanedge provides real-time quality data and trends (rejects, online KPI “quality rate,” track & trace with quality checks and process interlocking, etc.) to identify quality problems early on and take immediate corrective action.

With Germanedge solutions, quality can be measured (e.g., via quality rates in the OEE context), traced (via documentation, workflows, and traceability), and improved in a targeted manner (through integrated action control and checklists).

The result: fewer errors, more stable processes, more satisfied customers—and higher OEE.

Bermuda Triangle. Bermuda Triangle. Bermuda Triangle. Bermuda Triangle. Bermuda Triangle. Bermuda Triangle. Bermuda Triangle. Bermuda Triangle.

Costs. Time. Quality. Costs. Time. Quality. Costs. Time. Quality. Costs. Time. Quality. Costs. Time. Quality. Costs. Time. Quality. Costs. Time. Quality. Costs. Time. Quality.

Why OEE pays off – the step towards your Benefit:

When it comes to investments or optimization projects, OEE provides the business case right away. This is because the key figure allows the benefits of planned measures to be quantified in hard numbers—e.g., through reduced downtime costs, less scrap, lower material consumption, or improved plant utilization.

Based on our expertise, a 5% increase in efficiency is a realistic target, which proportionally increases output—an improvement that often pays for itself in less than 1.5 years.

Quality is the silent winner here: reducing scrap and minimizing rework not only increases OEE, but also strengthens customer confidence.

Turn OEE into Benefit– discover the hidden profits in your production!

The Germanedge OEE Benefit Calculator

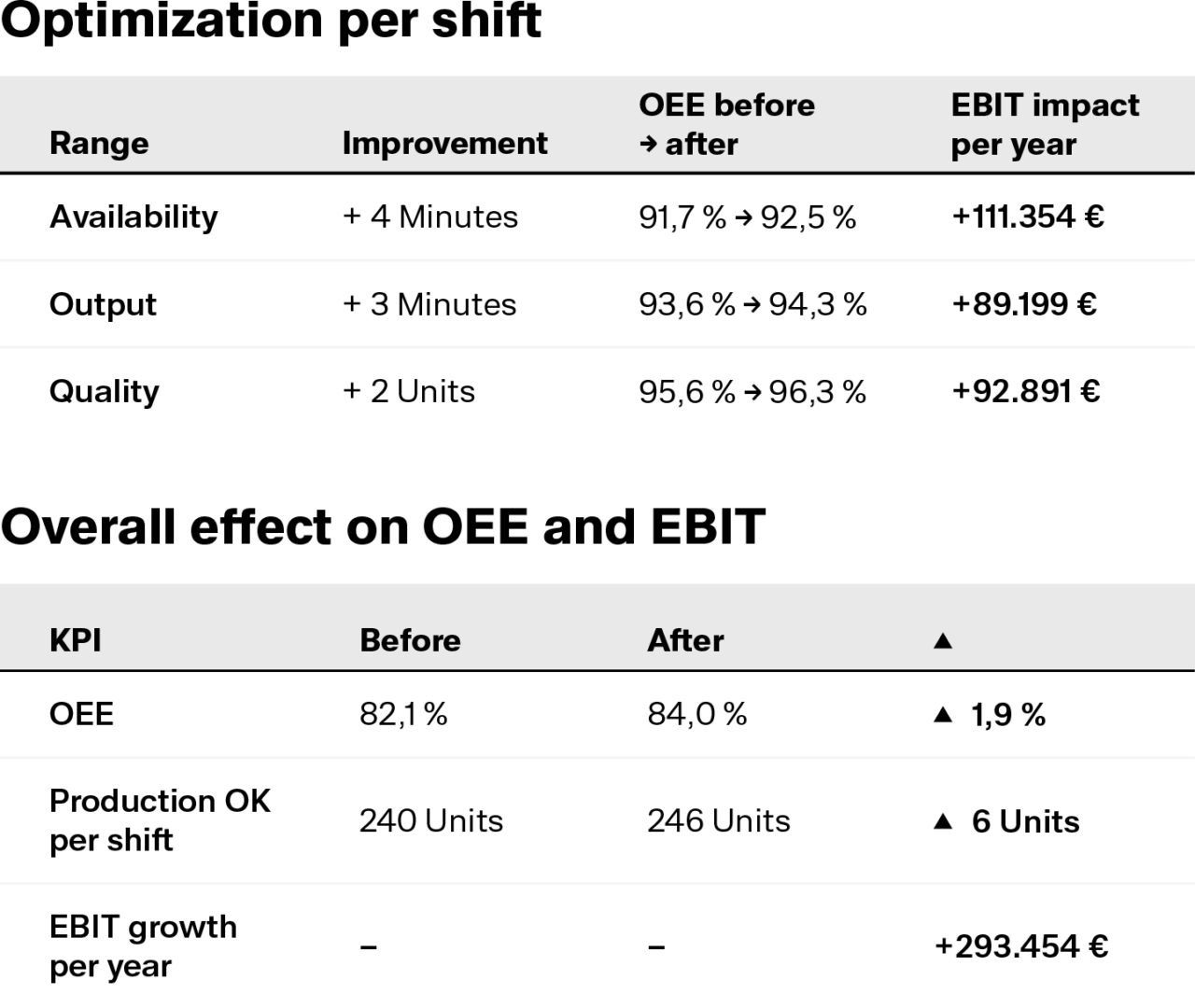

This is exactly where our Benefit calculator comes in. This tool translates your individual OEE data into concrete figures: What is the financial benefit in euros of reducing production downtime by 7 minutes and minimizing scrap quantities by 10 per shift, for example? The OEE Benefit calculator provides the answers. This allows you to see at a glance what potential has remained hidden in your production to date.

We have prepared a sample calculation for you, in which you can see the benefits and improvements in the figures at a glance. This calculation is based on OEE benefits as an example for a medium-sized manufacturing company (annual turnover of €250 million) using a conservative improvement approach:

The benefits of the OEE calculator at a glance:

- Customized Benefit analysis: You enter a few key figures from your production—e.g., current OEE values, planned optimizations, or investment costs—and immediately receive a clear calculation of the expected return on investment.

- Clear decision-making aid: You can see in black and white the potential for increasing the efficiency of your production. This gives you a sound basis for investment decisions and prioritizing improvement projects.

- Personal expert contact: Once you have tried out the OEE benefit calculator for yourself, you can discuss your results in detail with Michael Stöger, pre-sales expert for OEE at Germanedge, and have your questions answered – in a practical and non-binding manner. So you don’t just get figures, but also expert classification for your situation.

Calculate your potential – and ask our expert any further questions you may have!

Book an appointment for your personal benefit workshop with our expert Michael Stöger after you have tried out the OEE benefit calculator for yourself!

Your data, our calculator – get answers straight away. Don’t miss the chance to visualize your production potential and uncover concrete profits.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Michael Stöger

Pre-Sales Germanedge