Vetter Pharma-Fertigung GmbH & Co. KG

Vetter Pharma-Fertigung GmbH & Co. KG

Vetter is one of the world’s leading pharmaceutical service providers for

the aseptic filling and packaging of syringes and other injection systems – for the treatment of diseases such as multiple sclerosis, severe rheumatoid arthritis and cancer. The globally operating company supports pharmaceutical manufacturers from the early development of new preparations through to worldwide market supply. Vetter was founded in 1950, currently employs 5,500 people worldwide and has over 40 years of experience in aseptic filling and contract manufacturing.

Initial situation

There were repeated bottlenecks in Vetter’s QC laboratory capacities, which posed the risk of the laboratories becoming a bottleneck within the supply chain. Nevertheless communication with production and purchasing was not fully supported by technology. This made it difficult to integrate QC (in terms of processes and data) within the entire supply chain.

Specifically, for example, customer orders were accepted for which the laboratories were not fully involved in the evaluation process in terms of capacity feasibility. This resulted in high costs for short-term capacity increases. Bernd Gruber, Head of QC Service & Systems, comments: “The need for ever more precise laboratory capacity planning led to increasing costs, which we had to cover ‘manually’ and often ad hoc reactively instead of planned proactively.”

Consequently, a software solution was sought that would support the integration of the laboratories into the supply chain in terms of data and processes, as well as a simplifies the capacitive planning of QC resources.

Selection process

Vetter has been using the Planning Domain with its production planning tool since 2012. This includes the Planning Domain Manufacturing Workbench for capacity planning and detailed planning. Demand-side planning has also been carried out with the Planning Domain Enterprise Workbench since 2020. A trusting relationship has been built up with us through the intensive cooperation during this period.

An analysis revealed that Planning Domain also has a solution for laboratory planning in its portfolio with the LabScheduling tool. This fulfills the aforementioned requirements and, in particular, offers full integration into the existing production into the existing production planning solution and (via a certified interface) the SAP ERP used.

Project process

At the beginning, a rough project procedure was agreed in joint meetings with the planning domain. This consisted of several initial workshops in which it was clearly defined which functionalities and data were needed to fulfill the given requirements. It turned out that the time required to adapt the master data in SAP (in particular inspection plans) was in conflict with the rapid use of the software. The implementation was therefore carried out in such a way that outstanding master data adjustments were compensated for by temporarily maintaining the data in other sources such as Excel or Z tables.

With the launch of LabScheduling of the Planning Domain, an overview of the upcoming capacity utilization of the laboratories was provided. The workload can be analyzed and checked in detail at all required resource levels. In addition to the inspection lots from SAP QM, simulated inspection lots are also created in the tool, which anticipate the upcoming workload based on the transaction data from production and purchasing. This means that

the effects of changes in production can be recognized at an early stage and reacted to accordingly. The software was implemented as a fundamental step in 2018 without any delays.

Parallel to the launch of the software, work began on adapting the required master data in SAP. The integration of the data from the test plans was then completed by expanding the laboratory planning solution. In addition, some detailed adjustments were made to the logic in the software. Thanks to good planning and coordination on both sides, these adjustments were launched in 2020 without any delays.

“Overall, the project was well structured and there was close support from the Planning Domain experts. The jointly set timeline and the milestones defined in it were also adhered to,” says Gabriele Franke, Project Manager & Senior Key User Expert QM Applications.

An adjustment to fully integrate the stability studies, including their simulation, is planned for 2021.

Insights

Communication between the QC and production departments has already improved as a result of the workshops and a greater understanding of each other’s processes has been achieved. The use of the software has strengthened this considerably. In the initial phase in particular, master data was the key to successful laboratory planning. An incomplete data situation could be cushioned by proceeding in phases. In this way, the potential benefits of the software were quickly realized, while at the same time successively improving and harmonizing the required master data.

Anne Kuhlmann, Vice President Quality Control:

“The cooperation with the consultants and developers at ORSOFT GmbH was always friendly and professional. Thanks to the successful implementation of the Planning Domain’s LabScheduling solution, Vetter now has a tool for comprehensive resource planning within the Vetter quality control, for which long-term support, further development and maintenance by Germanedge will be guaranteed.”

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge

BBC Cellpack Packaging SA

BBC Cellpack Packaging SA

BBC Cellpack Packaging is part of the Swiss BBC Group with two production sites in France and Germany, employing 300 people. The company develops, produces and distributes flexible packaging solutions for the food and cosmetics industries. The products are exported internationally. Since 2019, BBC Cellpack Packaging has been a member of CEFLEX, a project that unites companies along the value chain and creates solutions for the recycling of flexible packaging.

Initial situation & motivation

At BBC Cellpack, there was no defined requirements planning process for the two production plants. The planning of material requirements was purely customer order-oriented, and there was no long-term material and raw material planning. As a result, raw materials required for production were not always available at the required time, which led to problems with delivery reliability. The aim of the launch of a software solution for requirements planning was therefore to improve the procurement and delivery process.

delivery process.

During an acquisition phase in spring 2019, BBC Cellpack Packaging was introduced to the Enterprise Workbench, the requirements planning solution from ORSOFT GmbH. The ORSOFT Enterprise Workbench (EWB) is an extension of the leading SAP ERP system and offers, among other things, requirements planning functions for this platform, as well as a wide range of visualization functions for a transparent overview of the entire requirements planning process.

The acquisition phase was followed by a proof of concept phase. During this period, the Planning interface was imported into BBC Cellpack Packaging’s SAP ERP test system. This gave BBC Cellpack Packaging a direct insight into the possibilities of demand planning with EWB on the basis of its own master and transaction data. Following the positive completion of the proof of concept, the detailed specification of the requirements planning process began in fall 2019, followed by the implementation of the Planning Enterprise Workbench for the requirements planning of the two production sites.

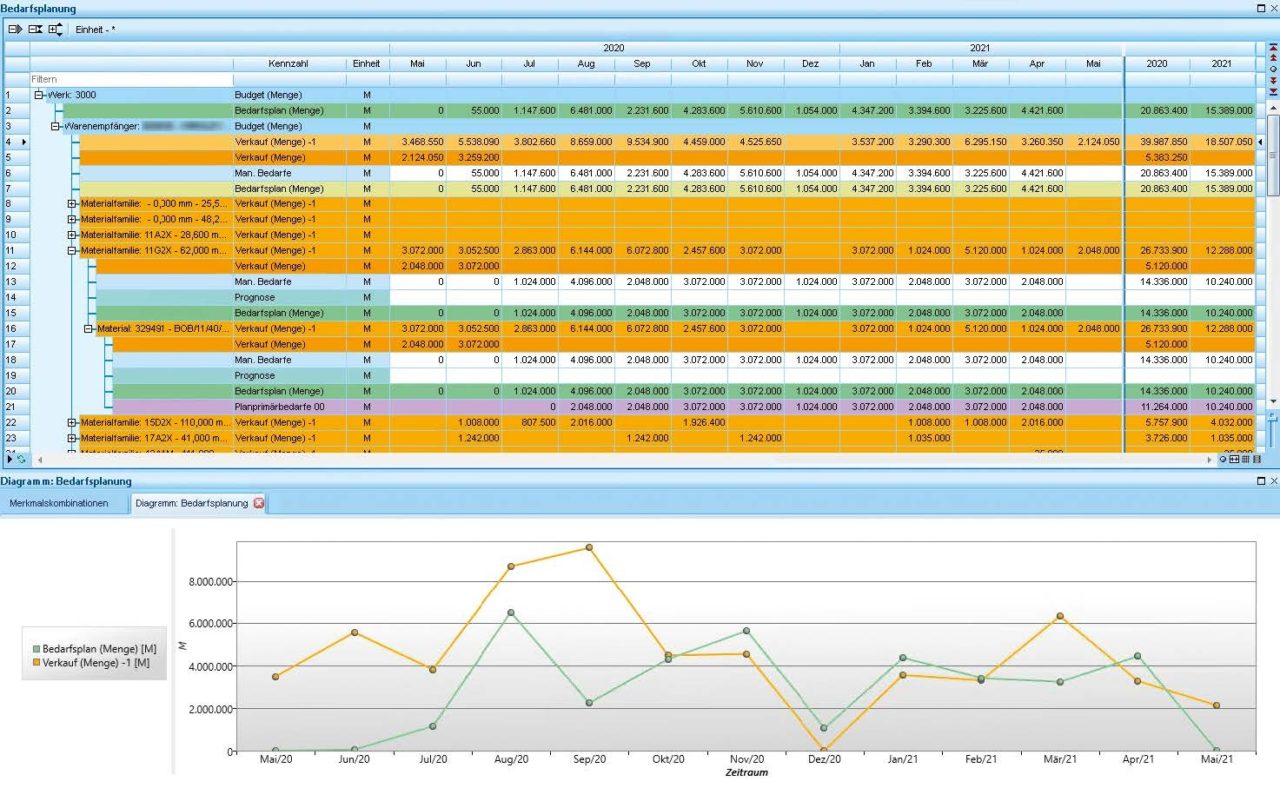

Requirements planning with the Planning Enterprise Workbench

The central planning object for MRP in the EWB are the characteristic combinations. The relevant combinations of plant, material, ordering party and goods recipient customer are automatically obtained from the loaded historical data at BBC Cellpack Packaging automatically from the loaded historical data. Together with the key figure model defined in the specification phase for the visualization of past sales and the maintenance of forecast data for future sales, the characteristic combinations are stored in table structures in the planning namespace in SAP ERP. Secondary data storage is not necessary.

Following implementation of the Planning Enterprise Workbench, requirements planning is carried out centrally by a planner at the site in Illfurth (France). This planner meets with the sales staff at regular intervals

sales staff at regular intervals to discuss future planned sales. This decentralized sales information is then entered into the Enterprise Workbench. Together with price information loaded via MS Excel, the EWB thus provides a central overview of planned sales volumes.

The sales scope is planned on the basis of the “material family” attribute, which is made up of three material classifications defined in SAP ERP. The planning folders in the Planning Enterprise Workbench enable the planner to maintain future sales at all defined planning levels (e.g. plant, material, sold-to and ship-to customer and material family). The maintained values are aggregated or disaggregated on-the-fly using defined distribution rules.

Requirements planning is accompanied by the results of budget planning. The budget planning results displayed at customer level are loaded into the EWB twice a year via a standardized MS Excel interface, disaggregated at characteristic combination level and mapped in the quantity and value key figures provided for this purpose.

The Enterprise Workbench also provides BBC Cellpack Packaging’s demand planner with a set of forecasting models. These recognize patterns (including trends and seasonality) from historical data which can be used to create forecasts for the future. The statistical forecast is supported by like profiles. These can be used to forecast the demand for planning objects based on the historical input data of one or more other planning objects whose demand behavior is the same or similar.

The result of planning at BBC Cellpack Packaging is a demand plan for each combination of characteristics. This is saved in a key figure. At the push of a button, planned independent requirements are created in the Planning Enterprise Workbench from these key figure values, taking into account loaded sales orders and allocation modes, and saved in SAP ERP. The daily MRP run in SAP ERP generates purchase requisitions to cover these planned independent requirements. These are used to stabilize the long-term ordering process.

System environment + Conclusion and outlook

The Planning Enterprise Workbench was easily integrated into BBC Cellpack’s existing system landscape. The Enterprise Workbench is accessed via a Citrix application.

After a short phase of downtime due to the delayed provision of the infrastructure in late summer 2019, the EWB was successfully launched within the time and cost framework defined at the beginning of the implementation and has been in productive use since February 2020. The underlying ORSOFT system landscape enables the smooth integration of additional users for demand planning and the mapping of other planning processes, such as budget planning.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge