Manage assets and equipment

Maintaining values

Technical devices, be they fire alarms, elevators, notebooks, laboratory equipment, pumps or entire plants and power stations, should not only function smoothly; they must also pay off on the bottom line. In addition, their operation must not violate applicable laws, directives or occupational health and safety and environmental regulations.

Synoset helps with this: the software structures, controls and enables the monitoring of all asset-related activities. A cost-benefit analysis of the assets is possible down to device level. The software provides a database that helps you to identify potential risks at an early stage so that you can take targeted countermeasures, allowing you to manage assets and equipment simply and efficiently.

Industry Asset Management

Mobile access at any time

Deadlines at a glance

Synoset stores when a device/system was purchased or rented, which warranty periods and service levels (SLA) have been agreed with the supplier and when the next scheduled inspection and maintenance interval is due. Thanks to active resubmissions, you never miss a deadline and are always on the safe side when it comes to legal requirements or deadlines.

Efficient, paperless workflows

With Synoset, digital documents and information can be assigned precisely to the departments that need to process them within the scope of operational processes.

The system maps workflows electronically and assigns deadlines to tasks and process steps so that you can monitor response times. It is also possible to regulate substitutes within the workflows. Synoset thus ensures fast and reliable processes.

Audit-proof documentation and archiving

All data is recorded and archived in an audit-proof manner. Thanks to Synoset’s close integration with common document management systems, changes are updated on an ongoing basis. The system supports you in complying with relevant industry norms and standards such as FDA CFR, ISO and ITIL, etc.

On all devices in all languages

Regardless of whether your IT infrastructure consists of Windows computers, Apple devices or smartphones with Android, Synoset can be used on all platforms. The software already supports a large number of languages. In addition to German and English and many European languages, Chinese, for example, is also available as a language package. Practically any language is possible on request.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge

Global asset management helps to meet critical infrastructure requirements

Critical infrastructures (“CRITIS”) are subject to special rules within the EU, such as the NIS Directive. In order to comply with these rules, and indeed to have an overview of all assets that fall under these rules, it makes sense to use a global enterprise asset management system.

With NIS 2, the EU will significantly expand its list of “critical infrastructures” (“CRITIS”) in the future. Companies that fall within the scope of the directive will, for example, have to record, manage and document all of their automation and security-related OT (operational technology).

A global enterprise asset management system in which data, dependencies, workflows and access authorizations are maintained in an object-oriented manner, i.e. in relation to each individual asset, has proven to be useful in numerous use cases. Several objectives can be achieved with such a tool:

- Process security, i.e. ensuring reliable and stable running systems

- Compliance with the NIS Directive and national legal requirements

- Passing audits

- Rapid processing of incidents and security problems

Overview, structure, documentation

Especially in the automation and control technology (OT) of industrial companies, there is often a lack of overview, structure and documentation. Neither are all hardware and software components, network participants and dependencies known, nor is there clarity about the up-to-dateness of operating systems, the assignment of authorizations or the allocation of IP addresses and much more. The complexity of a company’s technical operations cannot be mapped in conventional Excel lists, let alone kept track of.

Openness of the system, object-driven structure

As a company’s technical infrastructure is usually individual, an asset management system must in principle be open to everything, but still provide a clear structure and a good overview. Our system focuses on the object – be it machine XY or laptop XZ. Each object is first recorded with the most important basics – e.g. model, year of manufacture, serial number.

It is then enriched with extensive detailed information, such as responsibilities, dependencies and other metadata. This creates an agile object structure that provides a global overview of all technical assets and enables active monitoring of inspection, maintenance and warranty periods. Our asset management system remains responsive even with very large volumes of data – millions of objects/assets.

Your added value

- More transparency. Your employees get an overview of all assets and can see everything they are authorized to see

- More simplicity. Our system removes complexity. Employees only receive the information they need to continue working effectively. Everything else is hidden.

- Less workload. Extensive automation streamlines and accelerates processes. The system does what can no longer be done manually.

- More sustainability. Once the process chain has been defined, deadlines are adhered to. Process reliability through multi-stage approvals.

- More legal certainty. EU regulations are stored and compliance is supported by global asset management

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge

Cleanliness and food inspections in supermarkets

Cleanliness and food inspections in supermarkets are extremely important, as a lack of cleanliness not only leads to image problems, it also puts customers and employees at risk. To avoid this, inspections are carried out at regular intervals. However, these inspections are often documented on paper, which slows down the process and leads to unnecessary costs.

Our customers rely on our combination of asset, service and checklist management, including reporting options, to carry out all inspections reliably and document them at the same time. The entire inspection process is supported by our electronic checklists. This begins with the creation of recurring inspection tasks, which are automatically escalated via email. It continues with the execution of the inspection and documentation and ends with the creation of further tasks to rectify defects and update reports.

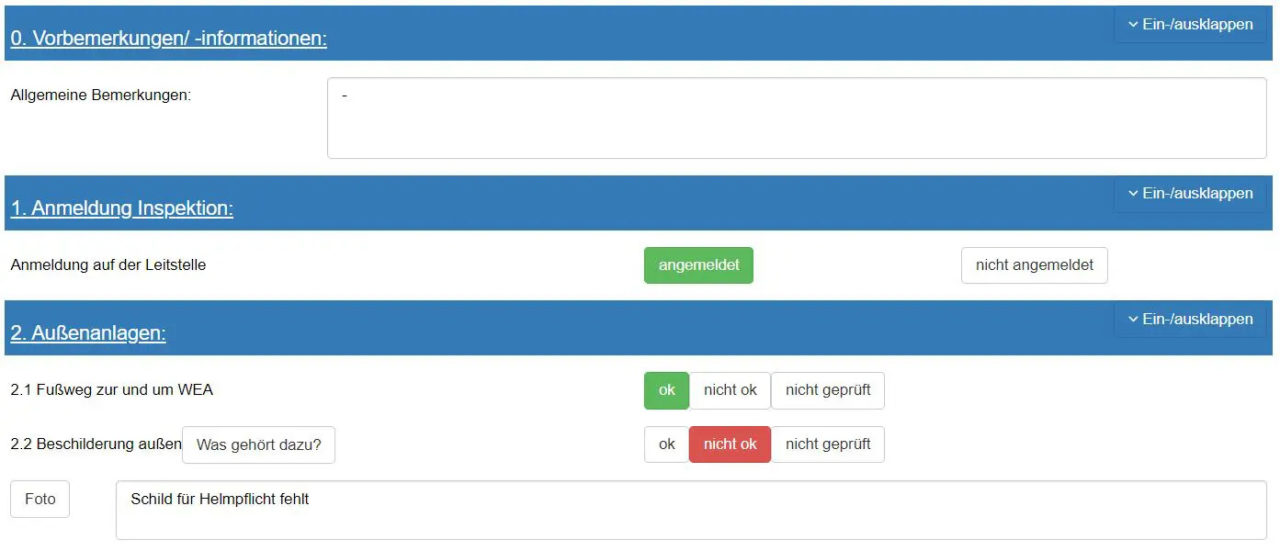

Inspection processes using checklists

Within the checklist, certain fields such as the name of the inspector, date and time of the inspection are automatically set so that time is saved and no incorrect entries are made.

The different areas are then checked and problems can be quickly documented and photos of problems can be taken using simple touch operation. You can provide the inspector with various types of assistance via image overlays.

During inspections, temperature violations at counters, for example, can be stored directly with rules in the checklist. For example, when an entry is made, a further task to check the counter is created directly for the service technician. The technician can then take care of the problem by a certain time, otherwise it is escalated automatically.

Reporting and reviews

By using a digital solution, it is only a small step to turn individual completed inspection reports into clear and comprehensive reports. This helps to quickly understand the correlations between individual inspections and to derive appropriate measures, so that cleanliness and food inspections in supermarkets can be carried out quickly.

Typical evaluations in this context are how many inspections were carried out in a period of time with how many defects were discovered or whether there are particularly frequent anomalies in an area. If, for example, the number of defects increases or stagnates over time, you should adapt your processes. Cross-location evaluations are also possible; if location A uses a different cooling system to location B, the number of associated problems will probably also differ.

Filling out dynamic checklists by touch

User-friendly control of the protocol by touch, directly with dynamic changes in the document and color support. If a problem has occurred, for example, the form expands to include a comment line.

Input options range from simple radio buttons and drop-downs to free text fields and signatures

Documentation of errors with image

A picture is worth a thousand words. That’s why many of our customers use the option of taking photos directly in the checklist to better document any problems that occur.

- Simply click on the photo function

- Possibility to draw directly in the captured image

- Image is displayed directly in the inspection report

Reporting options

Requirements and recurring duties can be transferred to responsible employees for processing using checklists.

- Visualization of measurements

- Display of process limits and exceedances

- Automatic calculation of trends

Various types of visualization

Here, for example, is a bar chart showing how many inspections were carried out by location and how many of them were deemed to have been passed. This gives you a quick insight into how the locations compare with each other and allows you to identify differences.

Cross-location reports

Here, for example, is an evaluation of the microbiological findings. Which areas show problems particularly often across locations? Where does it make sense to think about cross-site measures?

Search for inspections already carried out

A wide range of search options to find individual inspections carried out, for example in a specific period, by a specific inspector, even a direct search for entered answers is possible.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge

Management and maintenance using the example of wind farms

The management of wind farms is very complex. On the one hand, there is the complete asset maintenance with master data management, parcel management, contract management with terms, deadlines and different shareholdings. On the other hand, there is the maintenance process for each individual wind turbine with defects and their rectification. In many places, this is still documented on paper, which ensures neither audit-proof archiving nor efficient forwarding of information.

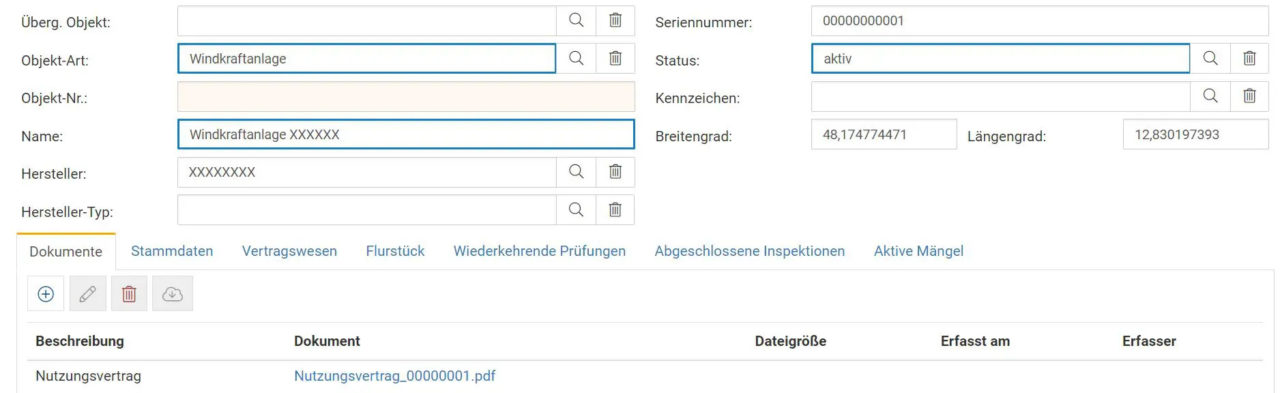

Management of all asset information

A wide variety of information must be managed for a wind turbine:

- Information on the wind turbine such as company data, contact details of the manufacturer, shareholders, manuals, parts, maintenance cycles, location

- Information on the plot of land on which the wind turbine is located, dimensions and location, owner and lease agreements, sometimes with the involvement of different people

- Contracts for the use of the wind turbine with contractual partners and deadlines

Everything is documented in our software and if input options are missing, either the customer or we can add fields.

When a contract expires, for example, our software automatically reminds you by e-mail.

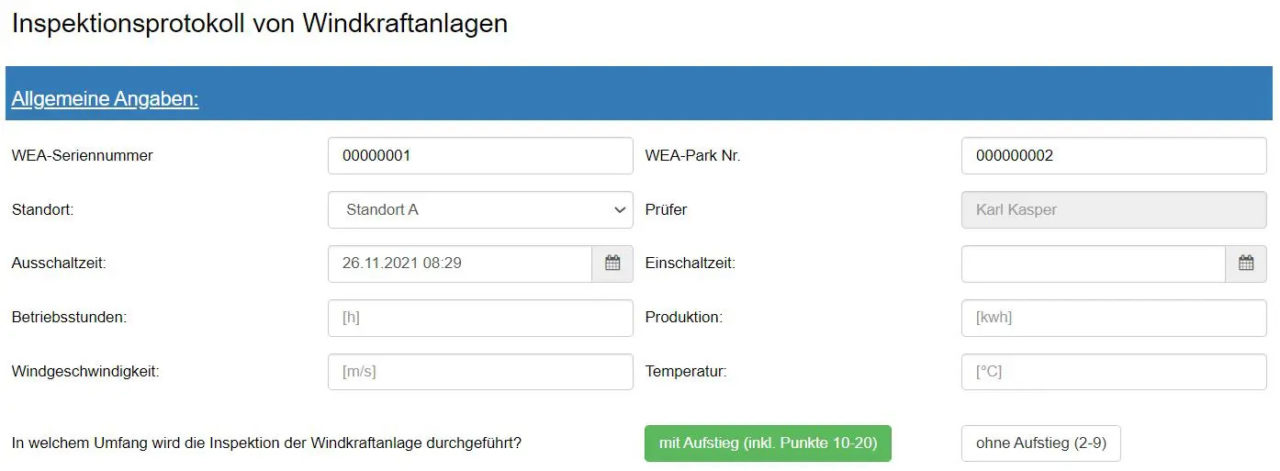

Complex maintenance process

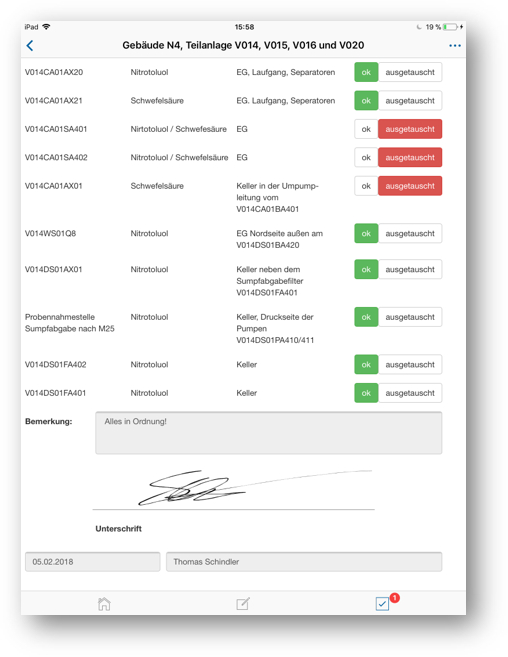

We can support you throughout the entire maintenance process with our customizable forms and workflows. This starts with the registration at the control center with signature directly in the document, continues with all inspections at the wind turbine and ends with the subsequent logout at the control center. In addition, all inspection points are stored in our solution in an audit-proof manner. If certain points are marked as being out of order, a photo of the problem can be taken directly on site. The problem is then used as a ticket in our system or, for example, an email with a list of defects is sent. The problem-solving process is also documented using checklists so that you always have a history of problems that have occurred and how they were resolved. In addition, it is always possible to see which defects still exist in which wind turbines.

A particularly practical feature for our customers is that many changes to the inspection report can be made without any programming knowledge using our simple drag-and-drop Checkware Designer.

Management of wind farms:

Clear list of defects

All documented defects can be clearly displayed at the end of the checklist, and the documented photos can also be displayed here.

- Processing via “app”, even offline

- Forwarding of defects, e.g. by email or as an additional task in our system

- Storage of the inspection report directly on the asset

Synoset with notification and requirement management

- Status of all conditions and notifications at a glance

- Attachment of documents, links and comments to operating objects (“Digital Twin”)

- Mapping of all inspection processes, i.e. single inspections, cycles and random samples

- Derivation of activities to be carried out via tasks, checklists or tickets

- Verification and documentation of compliance with important requirements

- Integration of service providers if external support is required for inspections

- Audit-proof storage of all information with versioning

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge