E-mobility in sight, but analogue in everyday life?

Our digital solutions for automotive supplier productions

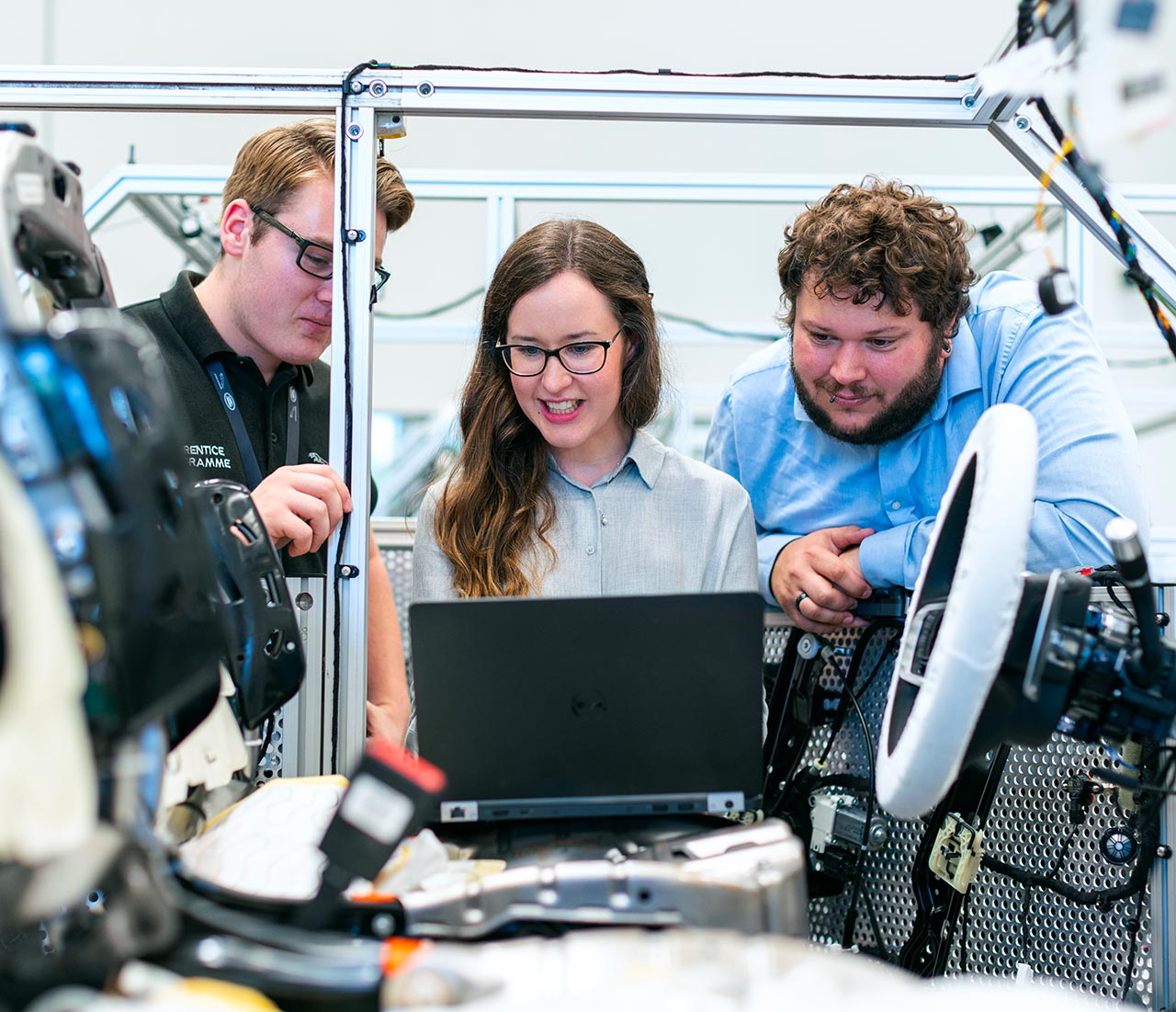

Your business as an automotive supplier involves innovation according to your own ideas and the specifications of leading automobile manufacturers. Your actions are driven by an eye for maintaining current mobility and developing new forms of movement. From engines to special hoses, you have efficiently adapted your processes and productions to the needs of the automobile manufacturers (private and business customers). You are agile where necessary and also stand for compliance with industry-proven processes in the production of your goods and products, so that the end customer can always enjoy the quality promise of the brand manufacturer and yourself.

Processes, products, quality management, and logistics must be interlinked just in time to ensure that the production lines in automobile manufacturing do not stand still. To this end, the company’s production lines and the delivery of components by its suppliers are efficiently controlled. The parts produced must last a long time and remain available until the end of service.

How automotive suppliers can master the challenges of production

We have the answers to these and other developments and are happy to take you through the digital solutions for your specific projects.

What Germanedge has to offer automotive suppliers

With EdgeOne we provide a fully integrated and micro-service-based architecture platform for all Germanedge solutions and the integration of industry-wide third-party solutions such as SAP and Microsoft.

Our solution package for all automotive suppliers is based, for example, on proven SAP standards and modules (PP for R/3 and the ERP S/4 HANA as well as PS, PM, MM, SD, etc.), which are used by leading brand manufacturers. In addition, we have created our own software solutions for the automotive sector, which are purely digital, cloud-supported, and fully integrated into your production landscape, providing an overview of the planning and execution of all processes, resources, and conditions in production. This means that the connection between parts production and assembly is also seamless.

We offer our flexible and scalable MES/control systems for the transparent display of all data relevant and critical to production from the entire IT landscape for suppliers and leading automobile manufacturers alike. Data can be recorded, controlled, and evaluated in real time at any time to ensure seamless and trouble-free production. These solutions are already in use throughout the industry.

Our total productive maintenance app for sustainable maintenance and servicing management is also part of the solution – from simple maintenance plans to predictive maintenance – in order to keep the entire production maintenance chain efficient, stable, and reliable. In the supplier industry in particular, maintenance cycles can be predicted and planned even more accurately and downtimes reduced, so that just-in-time production can be implemented in a future-proof manner.

Compliance with current quality standards (such as AIAG or ISO/TS 16949) is always guaranteed. Our agile development also ensures that future standards can also be covered. Our software is now in use at many automotive companies, where it ensures documented and transparent compliance with all relevant standards at all times. This enables us to promptly implement company- and industry-related changes in quality requirements.

We can provide practice-proven asset management of all IT and non-IT assets in the company (from desktops and notebooks to tools in production) for suppliers and comprehensive and trackable usage of all assets in a single system.

For the optimization of production and logistics, we offer targeted solutions for the automotive supplier industry. MES and WMS tailored to customer needs and integrated into a wide variety of software architectures (e.g. Microsoft Dynamics AX) have been in use for years. Our focus is always on the high-performance processing of large data sets (materials, products). It also gives us an extremely high level of reliability in just-in-time production and just-in-sequence delivery, so that the right part reaches the right customer.

Our many years of experience with international automotive suppliers mean that we can work with you to create and shape the mobility of tomorrow.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge