SCM-Software

Digitizing supply chains with SCM-software

Germanedge’s supply chain management software allows supply chains to be viewed as a holistic end-to-end process, enabling a whole new level of efficiency and transparency. This makes it possible to closely interlink strategic, tactical and operational planning tools. In this way, all supply chain management (SCM) activities – from the procurement of raw materials to the delivery of products – can be holistically optimized. Silo thinking between planning instances is now a thing of the past. SCM experiences a completely new form of efficiency and transparency.

The advantages of our SCM-software

Why SCM-software from Germanedge

Business processes at a glance: With our supply chain software, we orchestrate your supply chains as a digital twin and integrate all levels, both vertically and horizontally. Germanedge links strategic/tactical planning with operational planning.

Technology in our DNA: We have been developing successful SCM software for over 30 years and are a leader in algorithms. We are trusted by industrial customers from a wide range of sectors (link to references). Germanedge as an enabler of efficient supply chain management.

Industry know-how: Whether discrete manufacturing, process or series production or industry-specific applications – Germanedge supplies the necessary SCM system: as a standard application or as part of customer-specific adaptations.

The SCM system from Germanedge makes it possible,

- Continuously optimize inventories

- Reduce capital commitment costs

- Permanently reduce throughput times

- Use production resources efficiently (OEE)

- Drastically reduce waste quantities

- Minimize expenses for quality audits

- React quickly to changing customer requirements

- Avoid conflicts within the supply chain

Modules of our SCM-software

Sales & Operations Planning

Sales & Operations Planning (S&OP) Software enables companies to coordinate all sales, production and supply chain activities. Our SCM software includes tools for forecasting, demand planning, capacity planning and inventory management. In addition, S&OP facilitates collaboration between different departments and enables stakeholders to make informed decisions based on real-time data and scenario analysis.

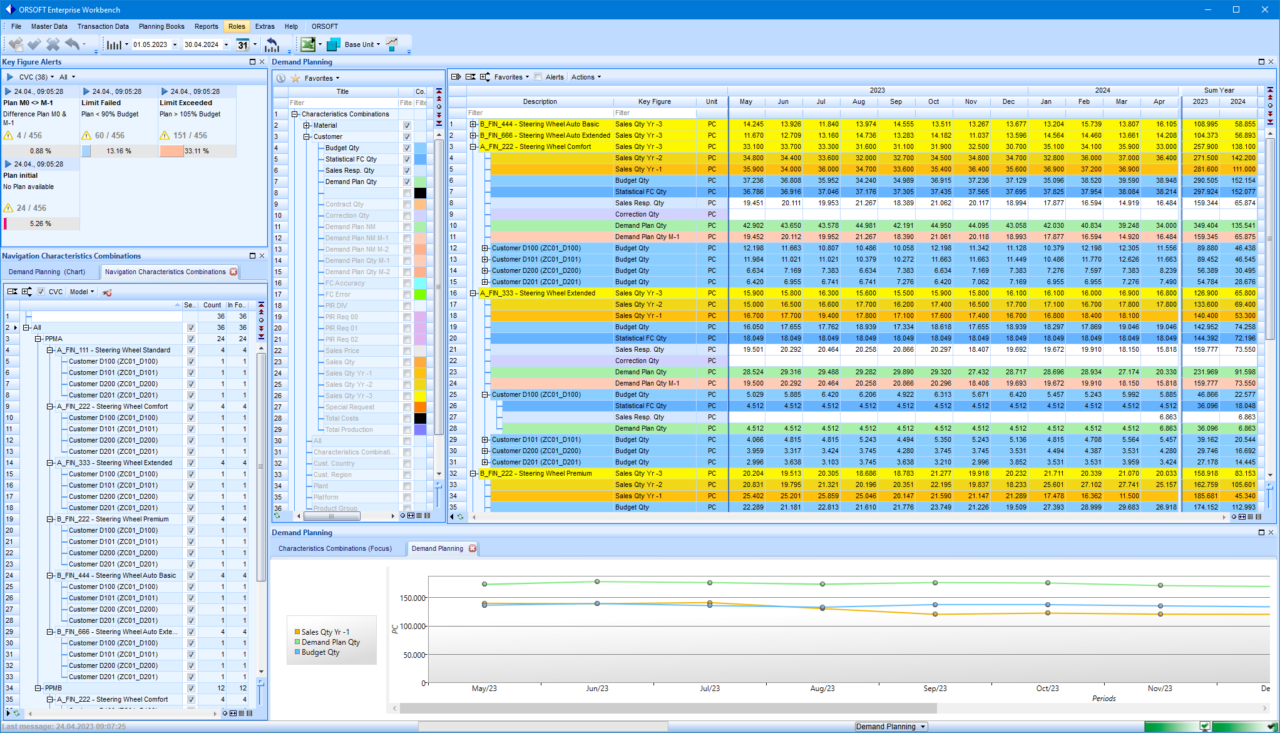

Demand Planning

With the help of demand planning, your company can accurately forecast customer demand and plan production & inventory accordingly. Accurate demand forecasts can be created based on the analysis of historical data, market trends and customer behavior. This is done with the help of advanced analytics.

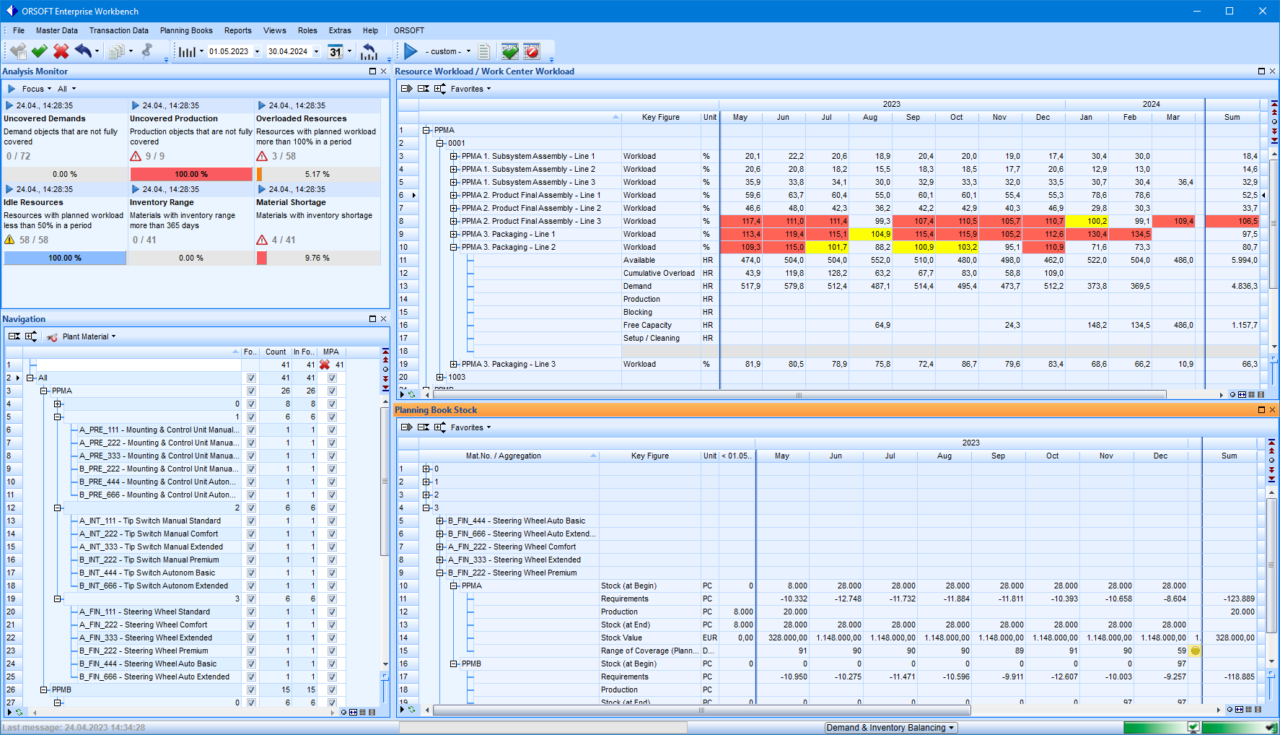

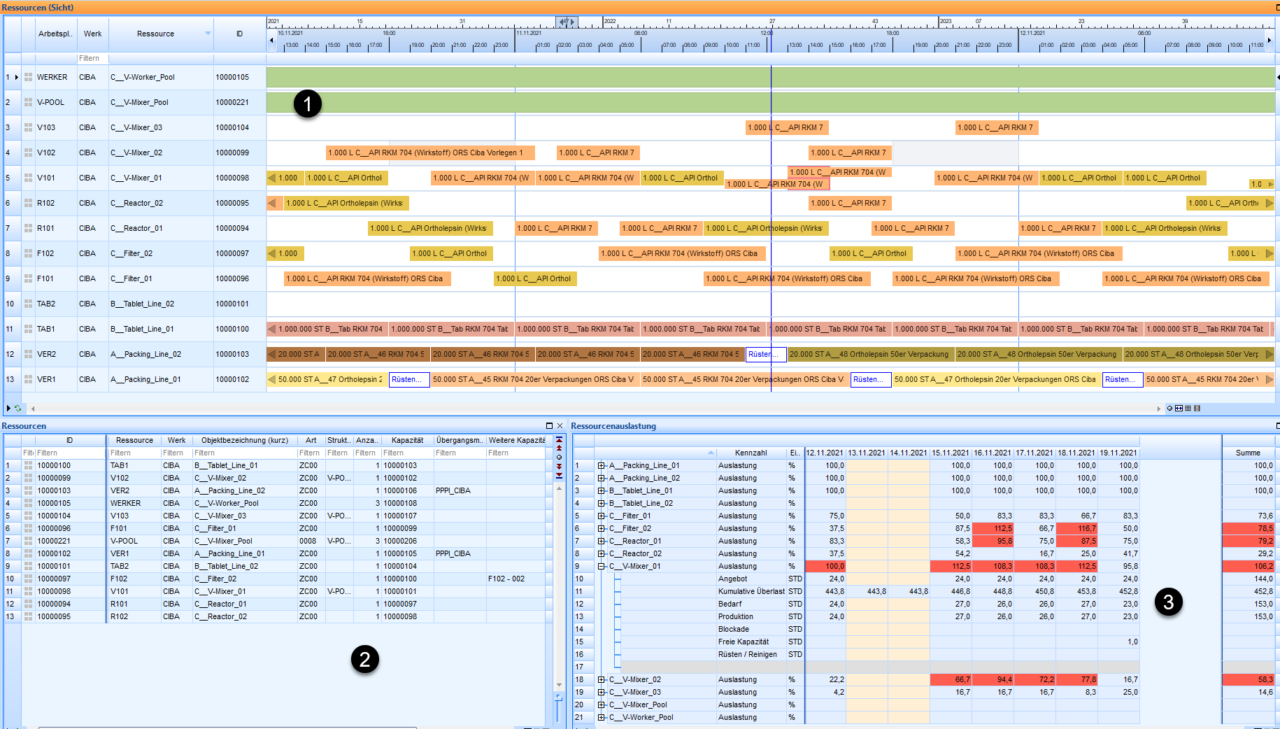

Supply Planning

With a targeted view of capacities and key figures, everything in supply planning revolves around this challenge: perfect customer service while minimizing inventory and operating costs. With the help of simulations, conflicts and restrictions in capacities and resources can be quickly identified, resolved and prioritized. This facilitates target- and solution-oriented communication with the customer.

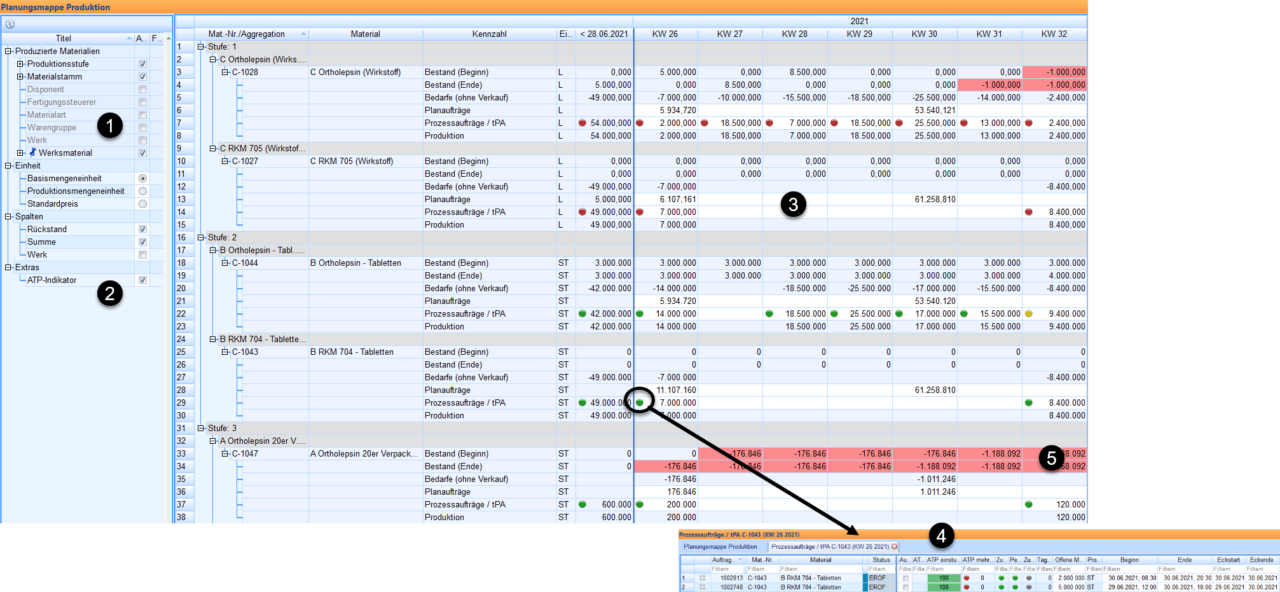

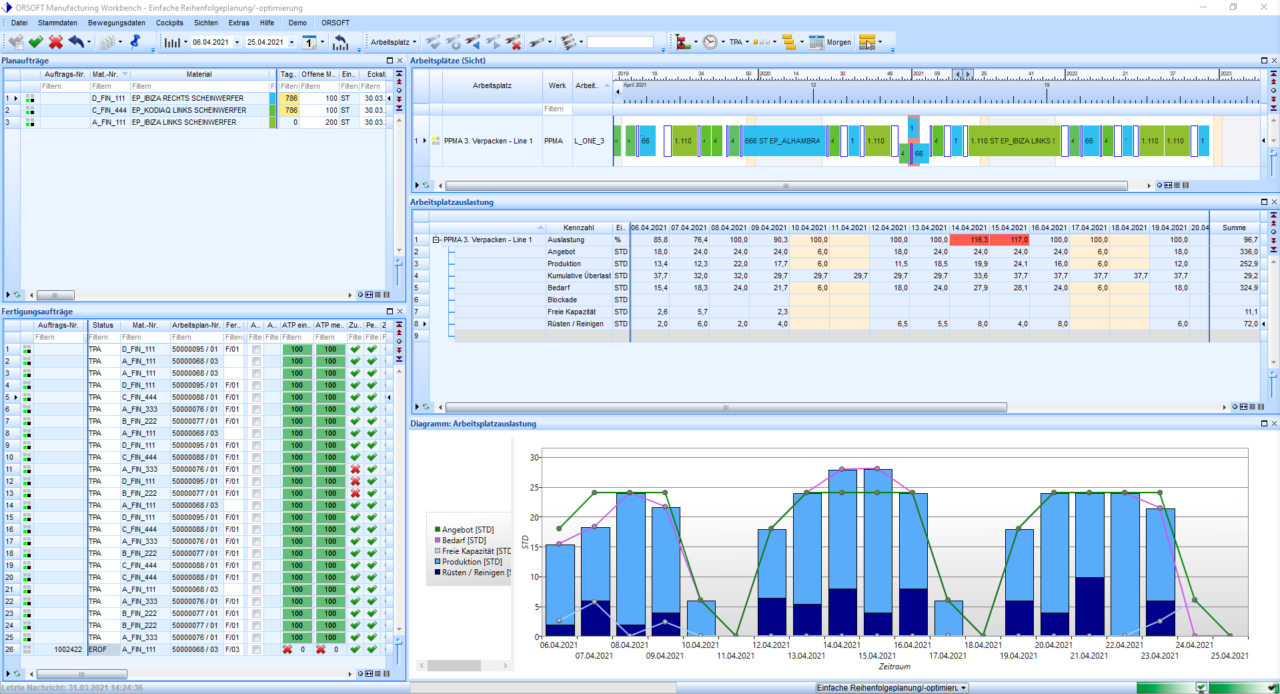

Advanced Planning & Scheduling

Advanced Planning & Scheduling is the operational-tactical tool in supply chain planning. It enables the interactive and simultaneous planning of all resources – such as available materials, labor and plant capacities. Simulations can also be used to optimize planning scenarios at any time. Specific solutions such as supplier risk management, autonomous planning / MRCP, personnel planning and lab scheduling complement the software solution.

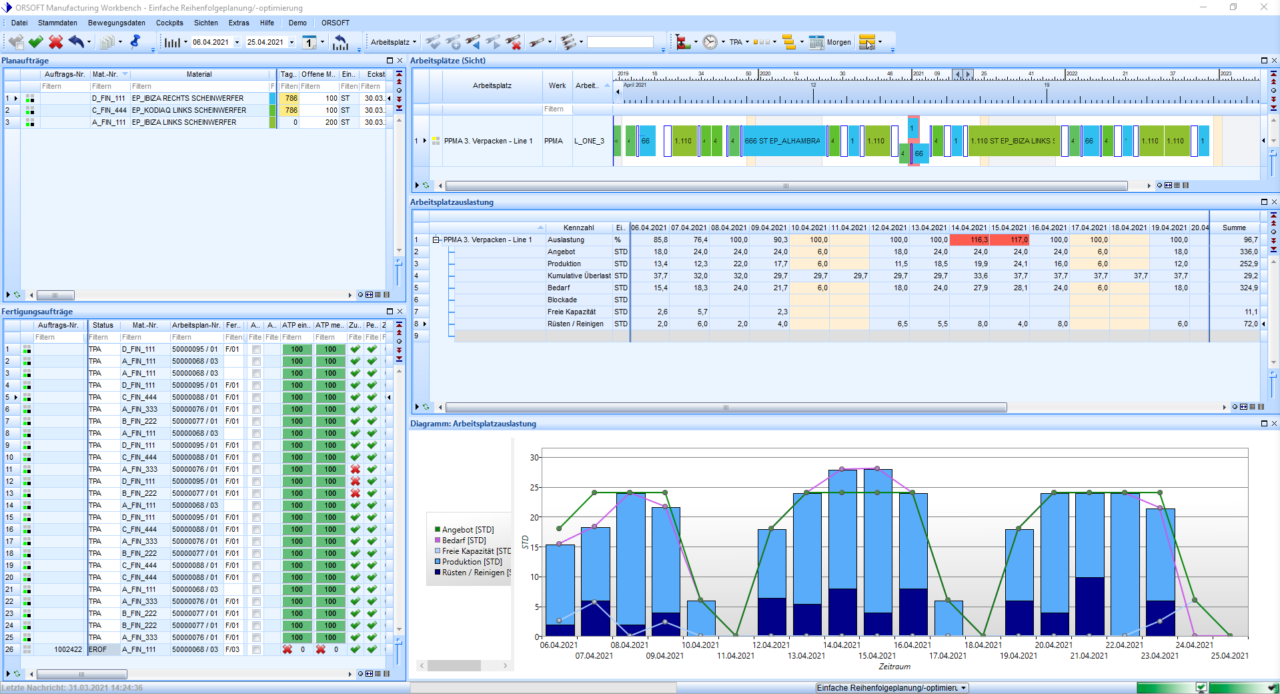

Production planning

Production planning is the operational tool of Advanced Planning & Scheduling. The so-called detailed planning enables the tracking of material flows and labor deployment as well as the provision of real-time feedback on the production status. Algorithms ensure that the best production plan is created from a large number of alternatives.

Integration of the supply chain management software

Our supply chain management software is designed as an application of our PaaS platform Edge.One. The modern framework acts as a central digital hub for all Germanedge and third-party applications. The goal: nothing less than the digital factory.

With our SCM systems, your existing ERP landscape can be expanded to include state-of-the-art planning functionalities. A certified interface for connecting to SAP® ERP and SAP S/4HANA also ensures simple integration into the leading ERP system.

The integration concept enables the Germanedge solutions to be piloted quickly. This is done on the basis of your data models – within 5 days.

Step-by-step instructions for integrating the SCM software at your company:

- You get in touch with us

- We show you the solution in a live demo

- We discuss the requirements and technical integration with you

- We support you with the integration and onboarding

Contact us or gain initial experience with our software and visit our solutions platform GermanedgeNOW.

Our SCM software is easily integrated into SAP:

- Little to no changes to SAP required

- SAP certified interface

- High flexibility with regard to SAP objects/structures

- Same language & data structures as in SAP

- Audit security thanks to the same authorization concept for users as in SAP

What is Supply Chain Management (SCM)?

Definition

Supply chain management (SCM) refers to the coordinated management of the entire network of business processes and activities involved in the manufacture and delivery of products or services from raw material procurement to the end consumer. The main objective of SCM is to increase the efficiency and effectiveness of the supply chain in order to maximize customer satisfaction while minimizing costs.

Supply chain management involves monitoring the flow of goods, services and information from the procurement of raw materials to the delivery of the final product to the end customer. The end-to-end approach of supply chain management ensures that the entire value chain – from purchasing, production and transportation through to distribution – is taken into account. This ensures efficient and effective processes throughout the entire supply chain at all times.

For whom is SCM software suitable?

SCM software is relevant for everyone involved in the production process.Our SCM software covers the functions for

- Demand Planner

- Supply Planner

- Production planners

- Purchasing

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge