The paperless factory

Much more than digital document management, cost reduction and sustainability potentials. Shaping the way to Factory 4.0 with a digital mindset

Imagine where and how much paper is used (or even wasted) in your daily business routine. Paper doesn’t blush, is a widely spread phrase. However, one thing paper is certainly not: fast, connected, adaptable, centrally saved and decentrally retrievable, as well as interface- and audit-proof. Even if many operational flows have grown over time and “somehow” work in everyday life, they are still far from being processes, and processes, in turn, are not necessarily synchronised with one another. That much is certain: the goal of the paperless factory is not just a central data provision, but a holistic data interaction.

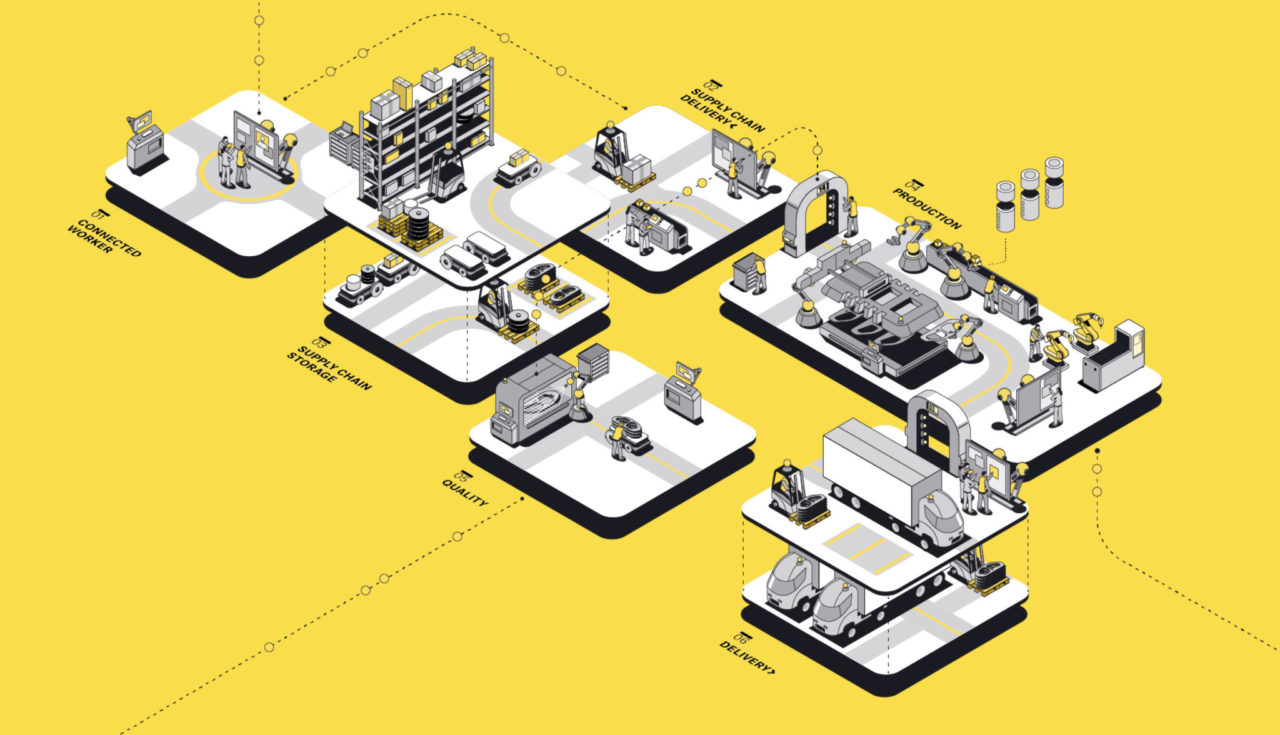

Indeed, the paperless factory stands for much more than the term might suggest: it describes a digital mindset for creating the Factory 4.0. By using a modern digital platform strategy, countless divisions – whether production, planning, logistics, quality management, maintenance, administration, plant management, infrastructure or security – can already be integrated into this business modelling.

Towards a paperless factory: goals and tasks in a nutshell

Data collection in day to day business environments: How digitalisation improves transparency, security and process reliability

Paper equals documents and documents equals document management: as simple this formula, as complex the processes behind. Unfortunately, the reality is often still as follows: scanning of documents, work instructions as PDFs or process and quality documentation in Excel sheets. Saving them in the central DMS is thus often the dead end of the digitisation process. We see those things in a different light. For us, digital document management is just an initial step towards a paperless and hence digital factory. That’s why we have also placed interactive documents, audits and checklists, digital workforce planning comprising employee skills and qualifications, digital asset management including procurement and contract management to our integral ingredient list. After all, employees will be working as connected workers in the very near future.

The Dimensions of the Connected Worker

The Interaction between Man, Machine and Process

Do you still know someone without a smartphone? If so, this kind of digital asceticism is the absolute exception. It goes without saying that nowadays we have data available always and everywhere. But what is it like in the workplace? It can often take you half a day to solve the information puzzle to complete your tasks on time and effectively. With our mission of the Connected Worker, however, this is really a thing of the past. Employees – as proactively acting entities – get their personal data-fed command centre:

Digital Shopfloor Management (dSFM):

Already an essential part of the paperless factory

Digital Shopfloor Management takes on an essential function on the way to the paperless factory. Its crucial tasks: creating transparency about processes and resources at production and workshop level and controlling them centrally. Topics of the daily shop floor meeting, such as daily targets, target/actual comparisons, scrap rates or safety topics – which are often still handled as “advanced paper economy” – become digitalised. This proved to be the first step towards a development from analogue processes into digital twin approaches, where not only the shop floor is digitalised, but also peripheral areas such as planning, purchasing and quality.

Our vision of tomorrow

The digital factory as an avatar of physical processes and their real-time control

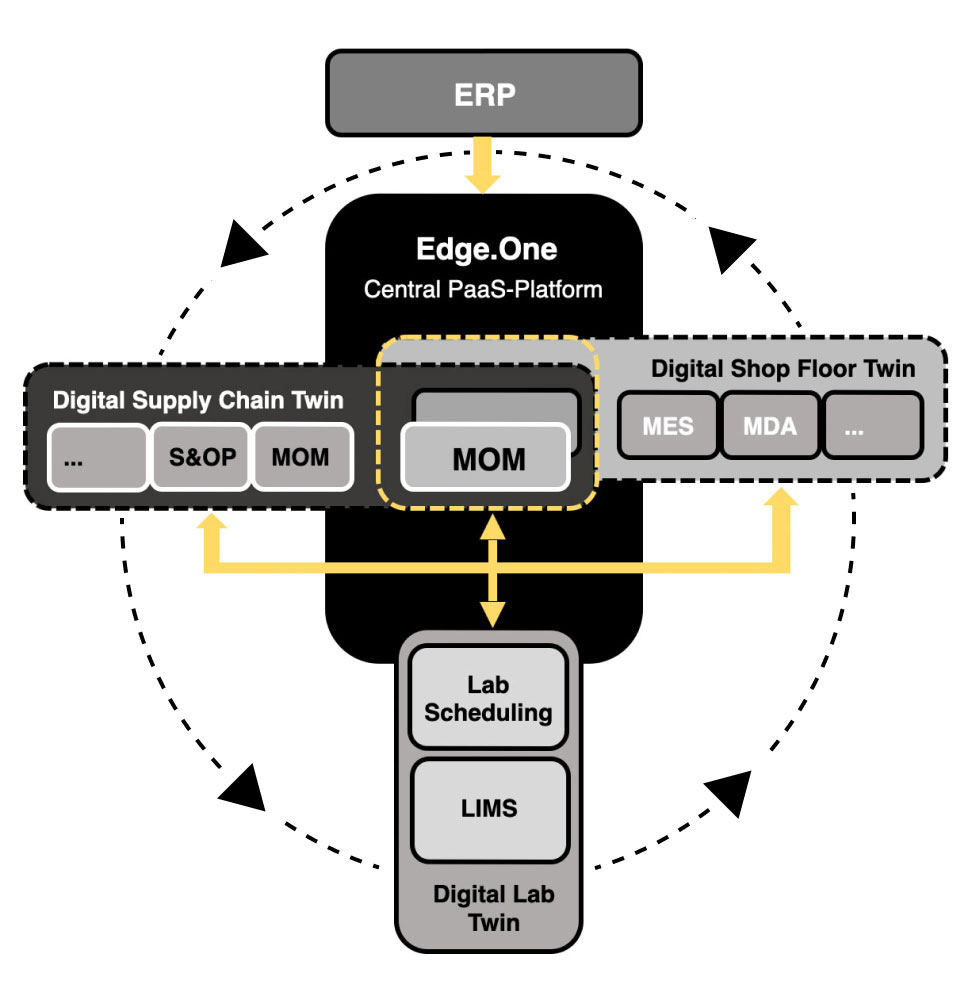

Digital twins as true-to-life reflections of physical assets and processes on shop floor, planning, laboratory and administration levels are the central tool for modelling the Factory 4.0. Their operation is interdisciplinary, as well as domain, system, process and application spanning. Through the application of meta and operational data as well as digital models, the digital avatars network their analogue equivalents among and with each other. With their help, processes are developed, application scenarios are defined and simulation-based and AI-driven applications are forced.

The Factory 4.0 thus needs a central digital hub that links and synchronises all digital twins. Even though the concept of Factory 4.0 is quite broad, it can still be easily transferred to industrial reality. This might happen through a Platform as a Service (PaaS) solutions such as Edge.One. The platform provides the digital anchor point for future smart extensions, for example through IIOT, augmented reality or blockchain applications.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge