- SME Initiative

-

Digital Factory

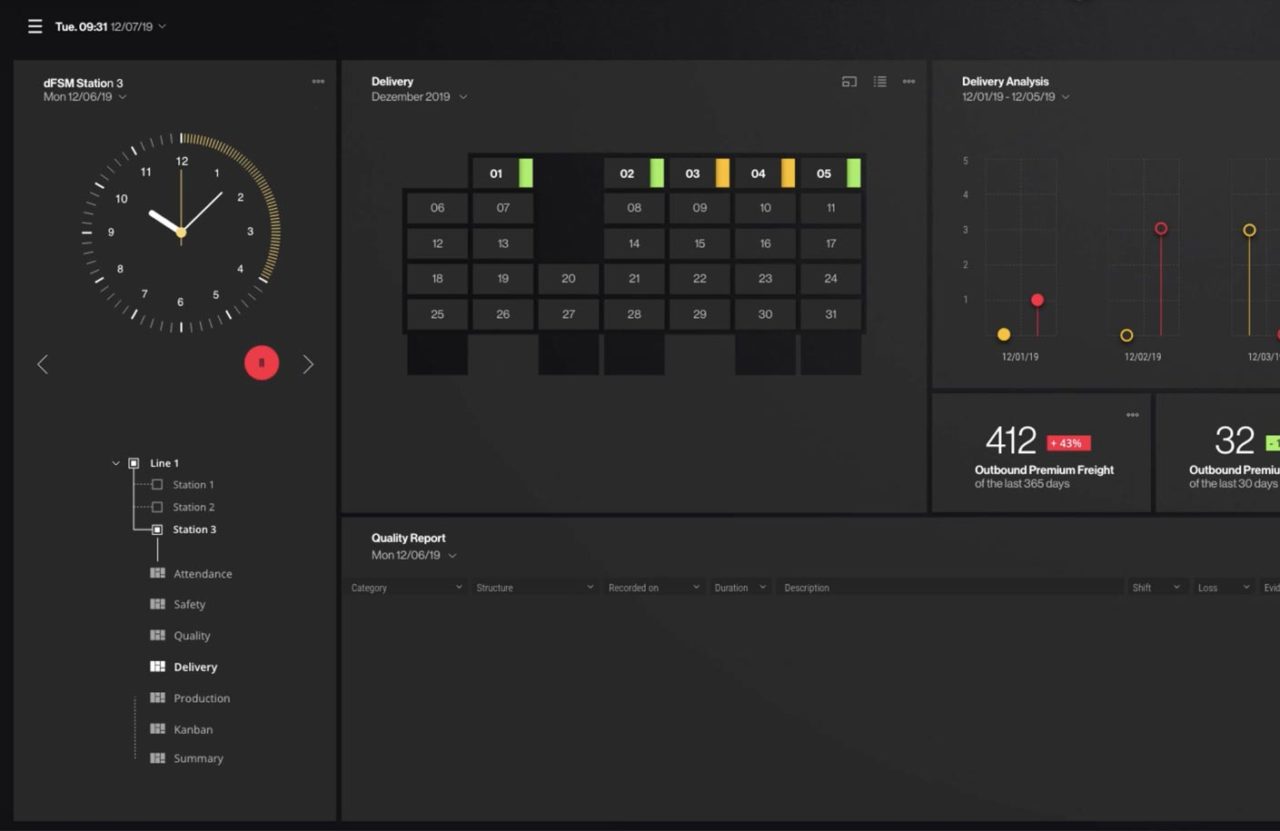

The Future of Digital FactoryOur elements of the Digital Factory

- MES/MOM Platform PaaS: Edge.One

- + – Production Management

-

+

–

Quality Management

- CAQ Software

- Quality Management Software

- SPC Software

- Complaint Management Software

- Manufacturing Document Management Software

- APQP Software

- LIMS Software

- Supplier Relationship Management Software

- Measurement Data Management Software

- Traceability Software

- Joint Technology Software

- Calibration Management Software

- Audit management

- + – Connected Worker

- + – Planning

Elements of the Digital Factory -

Solutions

Production ManagementQuality Management

- CAQ Software

- Quality Management Software

- SPC Software

- Complaint Management Software

- Manufacturing Document Management Software

- APQP Software

- LIMS Software

- Laboratory management software

- Supplier Relationship Management Software

- Measurement Data Management Software

- Traceability Software

- Joint Technology Software

- Calibration Management Software

- Audit management

Connected Worker -

Resources

Schlauer RaumCompanySupport

- Career

- GermanedgeNOW

- DE

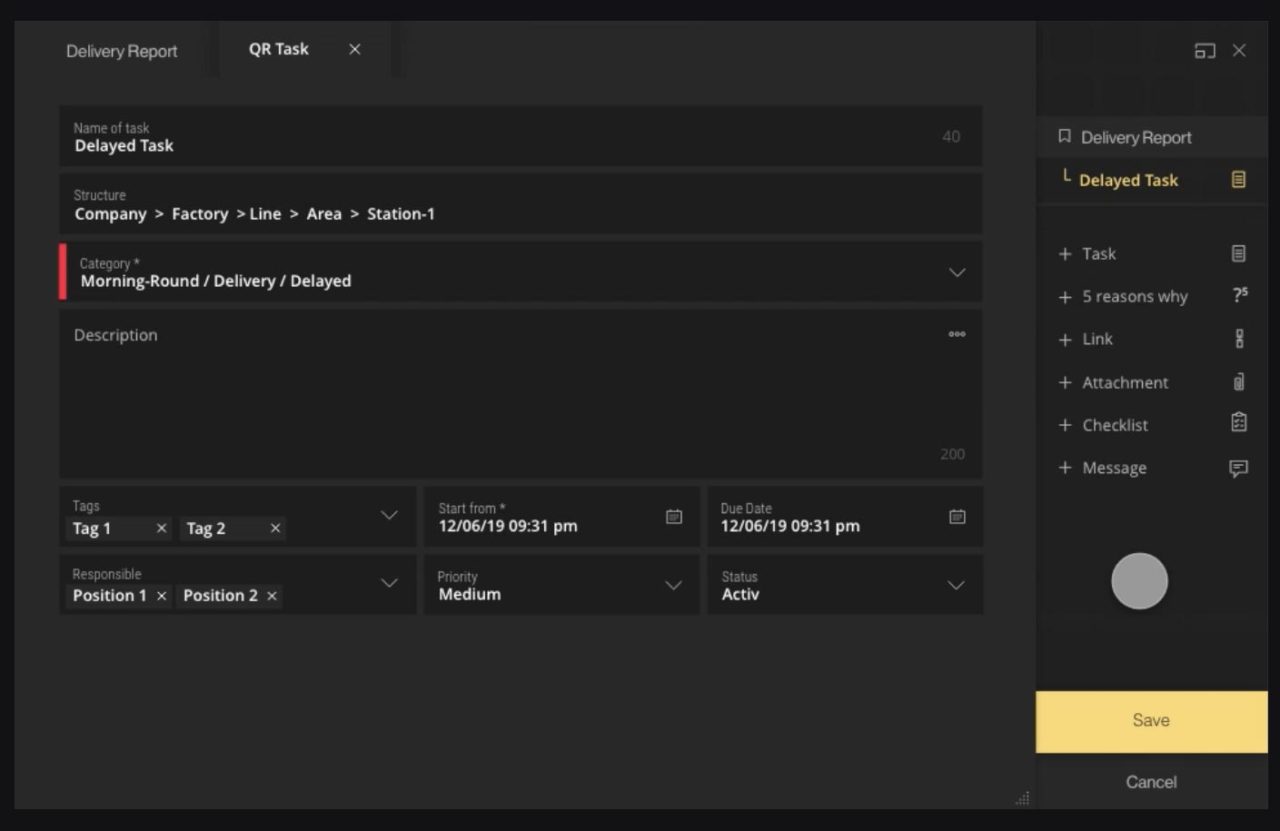

Tracking with our MES-based traceability solutions

Create visibility in production and logistics

In industrial production, a finely orchestrated interaction of all components, raw materials, production statuses, knowledge of storage locations, and other components is essential. Ensuring this on a daily basis is a major challenge for companies in various industries.

If audits, certification requirements, or recalls then come into play, it is essential to know what the production situation is like at all times. Data must be collected and the traceability of individual components, recipe components, raw materials, but also of finished end products must be guaranteed in the production software (ERP, MES, WMS).

Seamless traceability down to the individual part level

With traceability software, seamless traceability within production processes can be guaranteed. The main goal is to achieve transparency, from the raw part through the production process of the individual parts to the final product. This is made possible by linking production orders with unique serial numbers of the individual parts. The technology used for this could be, for example, barcodes, labels, FINs, lots, serial and batch numbers, data matrix codes, or RFID chips. If the solution is linked to the MES in a process-oriented manner, other shop floor data can also be included and linked. Consequently, almost every data record can be assigned to a product by means of track and trace.

A process-oriented traceability module linked to an MES for digital tracing offers the following advantages for your production:

Automatic digital tracking of each production part across different machines

More transparent production processes, e.g. through automated progress postings for orders (start, stop, interrupt, set up, error, etc.)

Comprehensive flow of information and rapid locating of individual production and logistics resources

Real-time overview of all faulty production processes for all machines, parts, stations, shifts, and users involved

Ability to limit recalls to exactly those workpieces which have an increased probability of defects

Our Germanedge solutions for MES-based traceability

Traceability with GEFASOFT MES Legato Sapient

With the extension “EB Tracking & Tracing” you get full transparency for your production line. Using an integrated data management system from ERP (e.g. SAP ERP or S/4HANA) in addition to the MES software Legato Sapient of the Germanedge company Gefasoft, Track & Trace not only allows for uninterrupted and user-friendly display of production orders, but also for supplementing them with real-time data from production on the various states, storage locations, fill levels, etc.

This way, individual production units can be tracked continuously. A production unit may comprise a single workpiece (discrete manufacturing, variant), a “batch”, or an entire “lot” of products.

Each manufacturing or production step can be precisely recorded for each individual production unit. Other data which is also retrieved includes:

- Process values and messages

- Status information (processing, quality status)

- Current and planned material usage (preliminary products, assembled parts, consumables, raw materials, recipes)

- Documented carrier and transport times

Furthermore, individual production units can also be blocked online via “black lists” and standard reports which provide information about production times at individual workstations or about the exact use of materials can be generated.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge

We need your approval

To contact us via our form or to download content, you must accept our cookies.

Alternatively, you can send us an e-mail to info@germanedge.com.