Connected Worker: working in the driver’s seat of digital production

Cleverly connected in the future of production

Man invented the machine to make life easier and not to live for operating machinery. It is therefore only logical that with one of the current major issues in digital production, the “Connected Worker”, human needs are once again the focus. The first machine invented by man did not make him more productive, but was rather an admission of his failure.

New concept for work between humans and machines

For decades, people strove to build the perfect machine. Nowadays, the focus has shifted to a new question: how can we enable people to work with a machine in the best possible way? “Connected Worker” is one of the trend terms of the modern working world. But it is more than just a trend. The Connected Worker is the state of the art and a key element in the concept of digital production. Because there is no doubt that even the best machine and the most intelligent programming are only as smart as the people operating it.

The Connected Worker as key to knowledge transfer

According to Gartner, Connected Workers are production workers who are able to use a variety of digital tools and data management techniques to enhance and integrate their interactions with both physical and virtual environments. This enables them to make better decisions more quickly, for example in order to optimize processes. The idea behind the Connected Worker is ultimately to make people interacting with machines smarter through networking, as networking is the key to knowledge transfer. The better connected we are, the more access to knowledge we have. And the more productive our activities become.

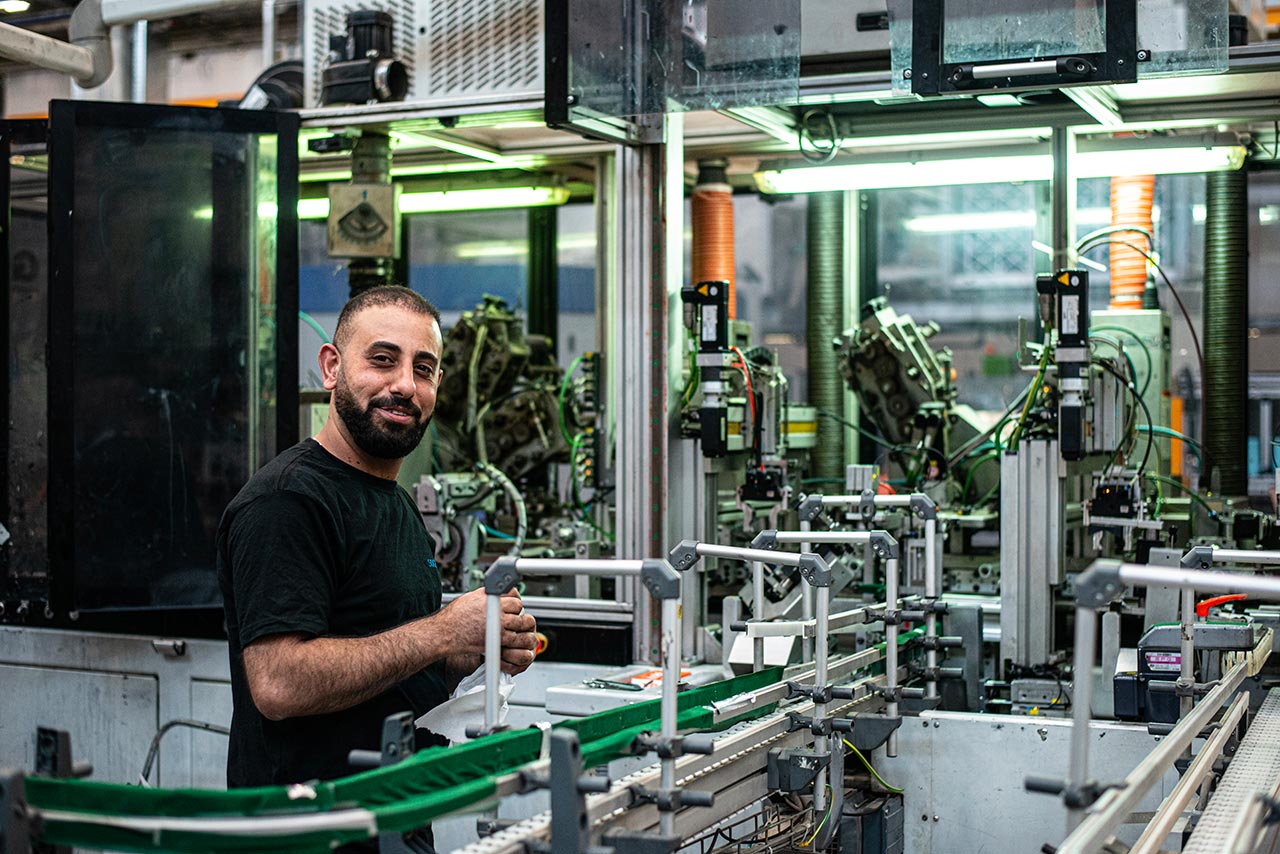

Employees as drivers of digitalization

Terms such as the “Connected Worker” are not only part of the future of digital production – they are already an integral part of successful companies. Germanedge firmly believes that the digital production of the future can only reach its full potential if people are integrated as an efficient production factor. We enable well-trained employees to be not only a part, but a driver of digital production.

By developing user-friendly UX/UI and software solutions for the MES/MOM world, Germanedge places the Connected Worker in perfect harmony with all digital applications in the production world.

Interaction for optimized production: the digital shop floor

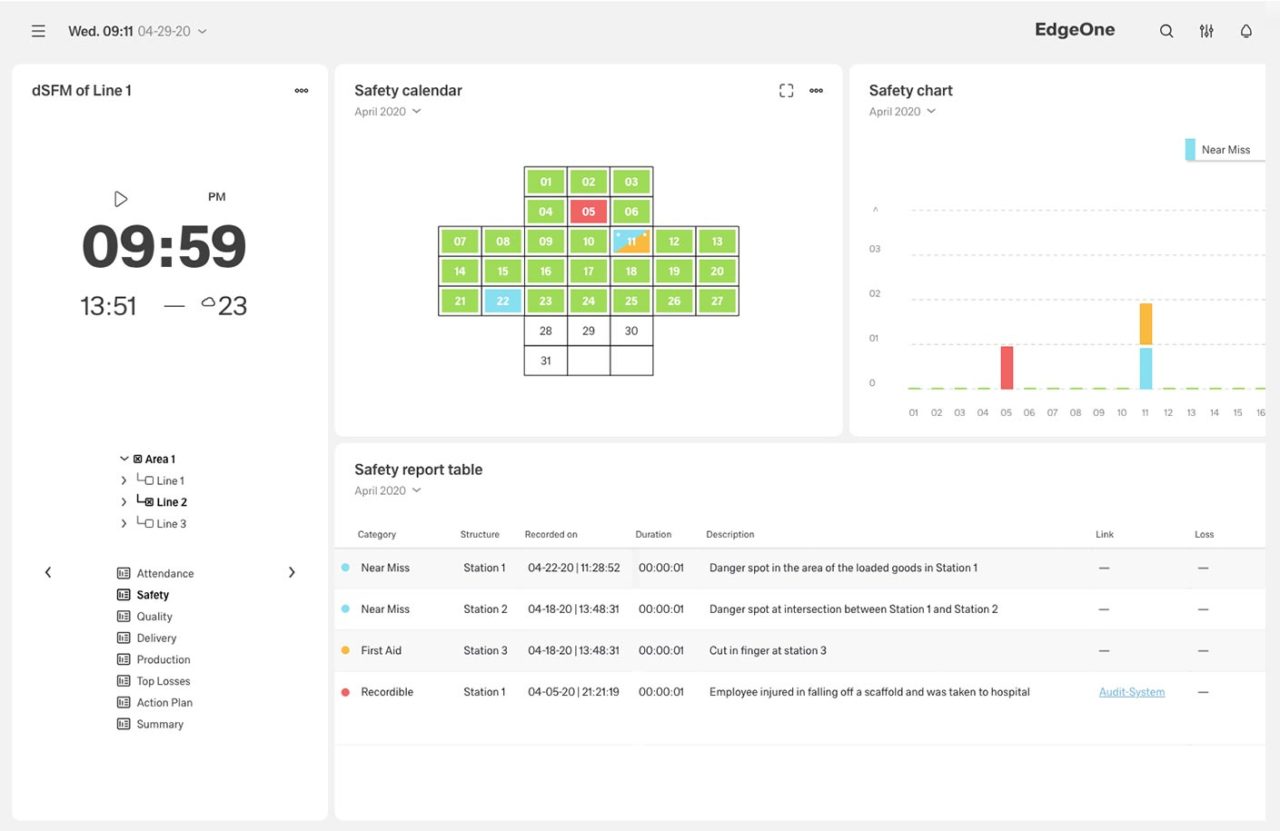

Access to production data, instructions on next steps, real-time connection to knowledge sources in other physical locations, these are just some of the applications that are already a reality. Germanedge offers various solutions that provide helpful support for shop floor workers.

With digital Shopfloor Management (dSFM), for example, we offer a solution that transforms a shop floor management meeting and all the resulting measures into a continuous digitally-based process. dSFM is an essential element for networked working – and for the implementation of the Connected Worker concept. It gives all employees a voice and has the potential to connect them worldwide and in several languages. It offers an intuitive and coherent application, relies on self learning and peer learning and thus reduces the need for training.

Our solutions ensure that people determine their own work instead of having it determined by machines. This not only has a positive effect on motivation and thus on productivity, it also ensures that the machines are trained until they can operate completely independently and intelligently, as envisioned in the smart factory.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge