How to integrate your manufacturing and testing technologies into your quality process

Software for Body Shop Management increases the quality & efficiency of your body shop

A slow pace is a luxury that can no longer be afforded in a digitalized world and integrated manufacturing process. But speed shouldn’t go hand in hand with carelessness – and it doesn’t have to!

The quality process already begins in the shell construction: Does the body shell meet the quality requirements, does the system produce the joining point correctly or is this the source of high costs and rework in the further production process up to the exclusion of several vehicles?

Body Shop Management solution for process and quality control

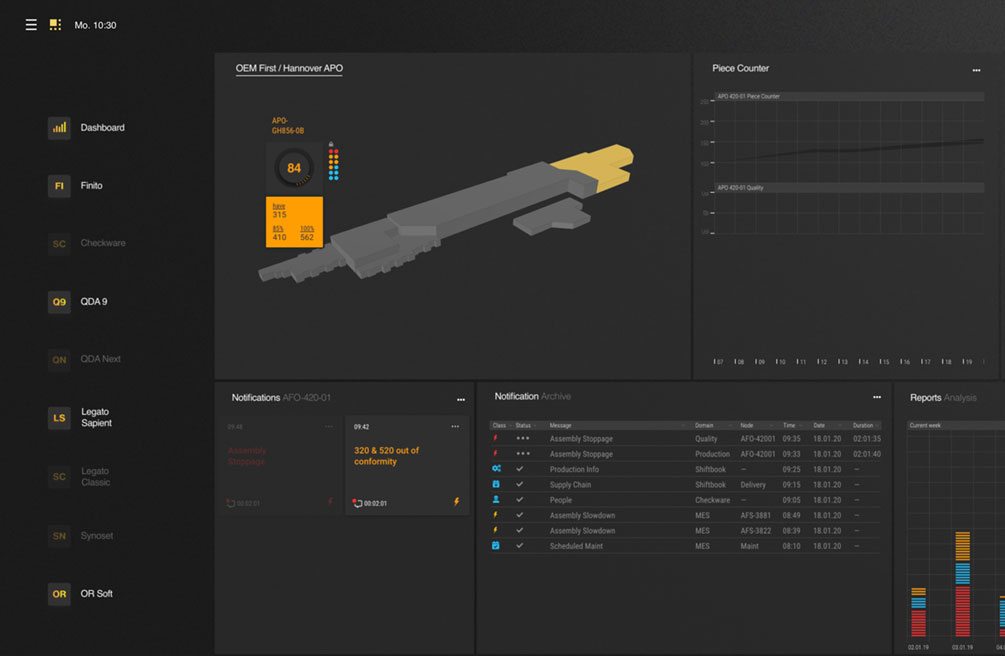

The Body Shop Management focuses on master data, process data and quality data of all joining points of a vehicle shell in order to detect problems in the body shop at an early stage and initiate remedial measures.

With our integrated software solution Body Shop Management you go into the analysis of process, master and quality assurance data for an immediate and long-term improvement of your quality processes in your robotics. Compared to manual data collection, our software can reduce inspection costs by about 40% and demonstrates increasing information flow. The costs for rejects can also be reduced by about 20%, due to the fewer production errors.

More targeted detection of errors

The basis of the technology is the combination of production and testing: possible production deviations are registered and stored by means of various modern testing technologies in order to make errors traceable and consequently correctable. The logic behind the body shop management solution is as clear as it is compelling: an industrial manufacturing product consists of many parts, sometimes several thousand. If errors are able to be avoided in the body shell, this considerably reduces costs in the subsequent process steps – both in production and in the effort required for data acquisition itself.

The Germanedge product provider QDA SOLUTIONS offers sophisticated software for Body Shop Management.

Our Germanedge solution for Body Shop Management

Increase quality and reduce costs

The Body Shop Management database system from QDA SOLUTIONS helps to keep an eye on process and component quality. It combines various manufacturing and testing technologies with which you can visualise and analyse process data linked to the quality data. This, in turn, enables a precise root cause analysis in just one system, independent of one of the sources. Targeted automated focus inspections drastically reduce inspection frequency and inspection scope.

This unique combination of assembly and testing technologies takes your production to the next level and strengthens quality and process reliability. The Body Shop Management module can be easily integrated into your IT environment and processes and works not only in the automotive industry, but wherever spot welding, ultrasonic, laser welding, clinching, gluing, laser cutting or other joining technologies are used and several raw parts are joined together to form a single workpiece.

Due to a considerable reduction in quality costs – especially scrap, rework and inspection costs – the introduction of the QDA SOLUTIONS Suite for Body Shop Management pays off after a short time. Do you also want to increase your first time quality and achieve more reliability in your production processes?

Get in touch!

Would you like to know more about our solutions? Then please write me using the contact form. I will get back to you as soon as possible.

Ludmila Lebedev

Sales Team Germanedge