That sounds simple. And in a way it is. Then why isn’t every company fully digitized yet? Some companies aren’t aware of the benefits of a digital factory yet. Others know the benefits but haven’t found their starting point yet. And then there are those that have already started building a digital factory but are stuck.

So, there are basically three different types:

Those that need more information

Of course you are hesitant to invest in new technologies and processes when you haven’t yet understood what a digital factory includes and how it can sustainably give you an advantage in the competitive struggle.

Those that haven’t found their starting point

A digital factory is complex and multilayered. It covers each area of the value chain und even exceeds it. It is understandable if you are not immediately certain at what point it would be best to start.

Those that don’t know their next step

Basically, every company that has to do with production is already digitized to some extent. However, to get ahead systemically and to be able to connect your different company areas technically, you need a suitable platform, software solutions, and a consultant by your side.

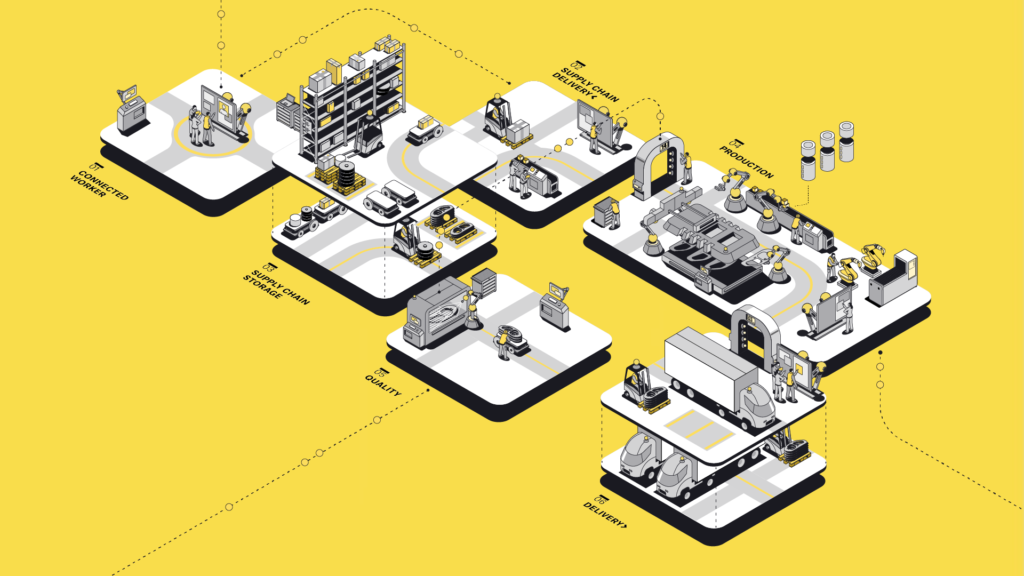

The Digital Factory at a Glance

The digital factory

- connects shop floor and top floor,

- includes the production and supply chain, factory operations and virtual planning,

- is based on real-time data,

- is constantly changing according to demands and new technologies, and

- is a flexible system that be extended step by step.

A digital factory is a network of digital models, tools and methods for the planning and commissioning as well as operations of a manufacturing company. A clear focus is on complete business processes as well as the planning and management of production processes.

The digital factory is made up of loosely interconnected applications. Each single one can be changed and optimized without interrupting the flow of information of the overall system. Areas that used to be standalones are connected and linked to create an ensemble.

This ensemble is a virtual image of reality in which data of the structure and resources, your machines, plants, and processes are summarized. This data is already available to you. It just needs to be made usable.

Competitive advantage: Getting Ahead with The Digital Factory

There are hundreds of solutions and technical applications you can improve the functioning of your company with. Not just because there are so many areas the digital factory can be used in.

The “components” of a digital factory are Machine-to-Machine capable machines, a powerful communication structure on the shop floor, a Manufacturing Execution System, cloud technologies for big data, tools that provide you with supply chain access, solutions for quality management, actual production such as digital shop floor management, and solutions that help you optimize the human-machine interface – and above all, a platform for connecting different technologies and relevant systems.

If implemented correctly, you can profit from benefits along the whole productions chain that grant you a clear competitive advantage:

- quicker time-to-business-impact

- higher flexibility

- less material losses

- increased production capacities

- smooth data flow

- complete transparency of production

- easier planning and production processes

- sustainability and production up until batch size 1

- sinking complexity of IT

McKinsey even delivers numbers on how strong the positive influence of a well-functioning digital factory can be. You can expect

- 30 to 50% reduction in machine downtime

- 10 to 30% increase in throughput

- 15 to 30% improvements in labor productivity

- 85% more accurate forecasting

- 15 to 20% inventory-holding cost reduction

- 10 to20% cost-of-quality improvement

if you digitize and connect the respective areas of your business accordingly.

The Best Time to Start with The Digital Factory Is Now

Before you can profit from all these noticeable improvements, some achievements need to be made. However, you shouldn’t try to adjust too many screws at once. The good thing is: You can basically start building the digital factory in every area.

It makes sense to consult an independent expert. They can evaluate your demands and where the quickest and the biggest potentials are hidden. Based on his evaluation, he creates a specification sheet that can be worked through.

Tips to Get Going

The biggest advantage when starting with the digital factory is simultaneously its weak spot: Because you have so many options, it can be hard to get out of the theory and planning phase. Here are a few tips to make the execution reality:

- Don’t try to cover every area at once.

It is enough to start with one area. You can integrate additional business areas at any time. If you start with all of them at once, however, you have too many construction sites.

- Keep your goals small.

Once a goal is no longer concrete, too many hurdles appear. Misunderstandings happen und motivation gets lost on the way. Therefor, define small goals that are attainable in a foreseeable timeframe.

- Have a clear vision.

Even when going step by step you should never loose sight of the big goal: the digital factory. Create a change story: How do the current situation and the desired situation differ? That motivates and keeps you on course.

By the way: Once the first steps have been made, the execution of the digital factory can easily be accelerated.

Slowing Down to Strategically Start Executing the Digital Factory

When a company struggles after the first few steps and can’t get ahead on the journey to the digital factory, it is usually because they haven’t taken the tips from above to heart: They either had no clear strategy or too big goals, lost sight of their overall goal or didn’t have a well-enough implemented platform on which the different solutions and tools can work together.

But even in these cases everything is still possible: What is already there can be used to take next steps and build on. What is missing can be added: A missing strategy can be created. Goals that are too big can be broken down.

You already have most of what you need. At most you are missing two things: An independent consultant who can create a specification sheet for you, and a software provider for the technologies that you need to execute your road map. We can help you with the latter.