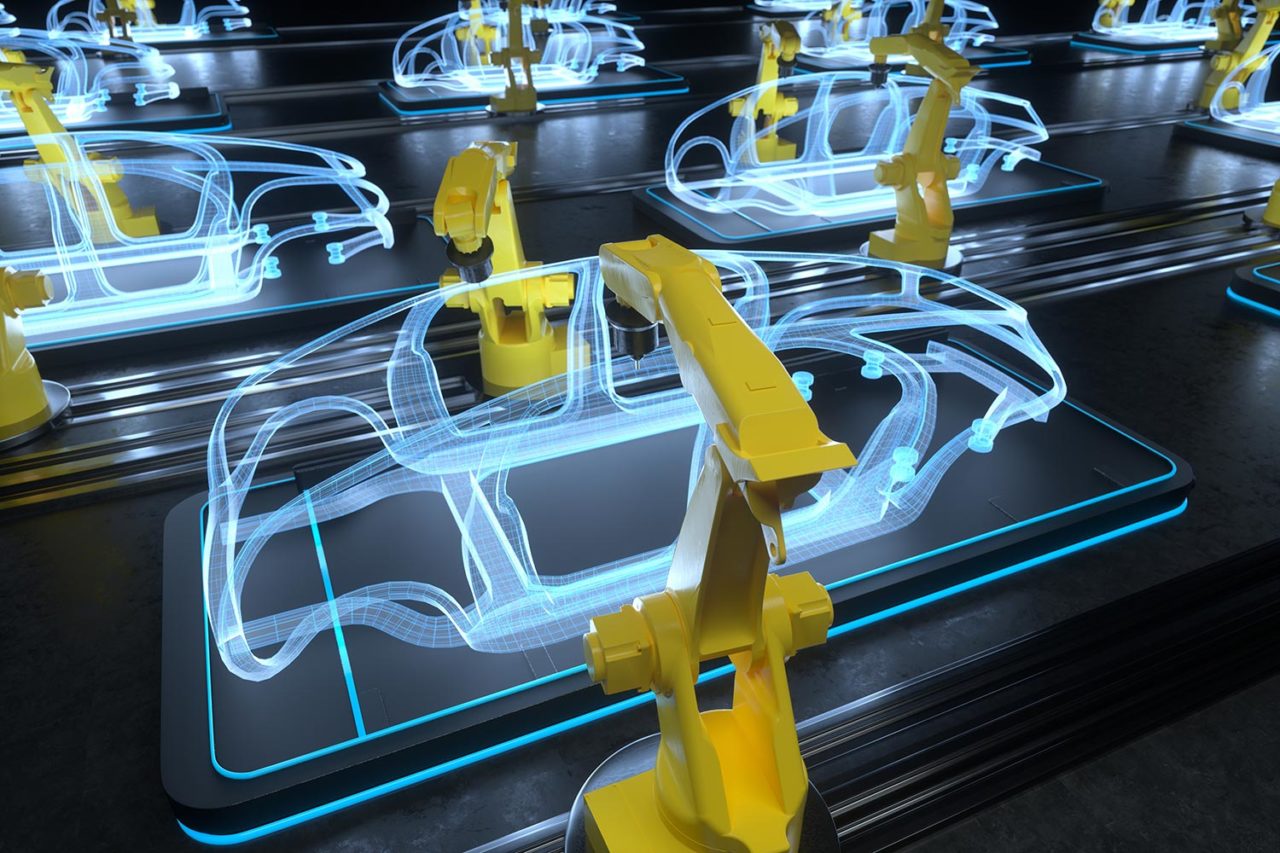

Digital car production starts today

Our digital solutions for the automotive industry

For you as an automotive manufacturer (automotive OEM), the mobility of society comes first, and in many cases has done for more than 100 years. It is not only about getting people from A to B, but also about emotional contact on the journey, so that the brand comes alive every day. New agile, digital production processes enable you to get even closer to the customer and to keep your brand promise time and again.

The value chain is more complex today than ever before. From the idea for a new vehicle to its planning, production, delivery, service, and end-of-service, many processes have to interlock and many changes are already underway.

Mastering challenges in car production

We have the answers to these and other developments and are happy to take you through the digital solutions for your specific projects.

What Germanedge has to offer car manufacturers

With EdgeOne we provide a fully integrated and micro-service-based architecture platform for all Germanedge solutions and the integration of industry-wide third-party solutions such as SAP and Microsoft. Our comprehensive package for all car manufacturers is based, for example, on the industry-proven SAP standards and modules (PP for R/3 and ERP (S/4HANA) as well as PS, PM, MM, SD, etc.). In addition, we have created our own software solutions for the car manufacturing sector, which are purely digital, cloud-supported, and fully integrated into your production landscape, providing an overview of the planning and execution of all processes, resources, and conditions in production.

Leading car manufacturers rely on our flexible and scalable MES/control systems for the transparent display of all production-relevant and critical data from the entire IT landscape. Data can be recorded, evaluated, and controlled online in real time at any time to ensure seamless and trouble-free production.

In addition, we have integrated solutions for future-proof maintenance management – from simple maintenance plans to predictive maintenance – in order to keep the entire production maintenance chain efficient, stable, and reliable. In the automotive industry in particular, maintenance cycles can be predicted and planned even more accurately, thus reducing downtimes.

Compliance with current quality standards (such as AIAG or ISO/TS 16949) is guaranteed, as is the implementation of future standards. Our software is now being used by many industry leaders, where it ensures documented and at all times traceable compliance with all relevant standards.

We can provide practice-proven comprehensive asset management of all IT and non-IT assets (from desktop, notebook to production tools) for car production and the comprehensive and trackable accounting of the use of all assets in a single system.

For the optimization of production and logistics, we offer targeted solutions for the automotive industry. MES and WMS tailored to customer needs and with all individual functions and integration of a wide variety of software architectures (Microsoft, SAP, etc.) have been in use for years in various production facilities and logistics centers of many car manufacturers. Our focus is always on the high-performance processing of large data sets (materials, products).

Our many years of experience with leading car manufacturers mean that we can work with you to create and shape the mobility of tomorrow.

Get in touch!

Would you like to know more about our solutions? Then please write me using the contact form. I will get back to you as soon as possible.

Dominik Weggler

Sales Team Germanedge