APQP-Software - Advanced Quality Planning Supports Improvement in the Production Process

Integrated Advanced Quality Planning supports continuous improvement in the production process

Integrated advanced quality planning is the basis for competitive products and more efficient production. Advanced Product Quality Planning (APAQ-Software) ensures that you check and improve your products already during the planning and development phase.

By preparing, analyzing and documenting your production data, our APQP software gives you new confidence in your processes and in planning the quality of your products in advance. Combined with integrated complaint management software, this helps you proactively avoid expensive product recalls and customer complaints. Customer satisfaction and your reputation as a manufacturer increase significantly – and remain secured in the long term.

With our solution for integrated advance quality planning, it is possible for all geographically distributed and cross-departmental teams to access the relevant quality management systems at any time.

APQP is often a prerequisite for compliance with quality standards and certifications in the automotive industry, such as ISO/TS 16949, QS 9001 and VDA. Our APQP software QDA enables you to achieve these standards and supports you in compliance and certification.

Advantages of our APQP-Software

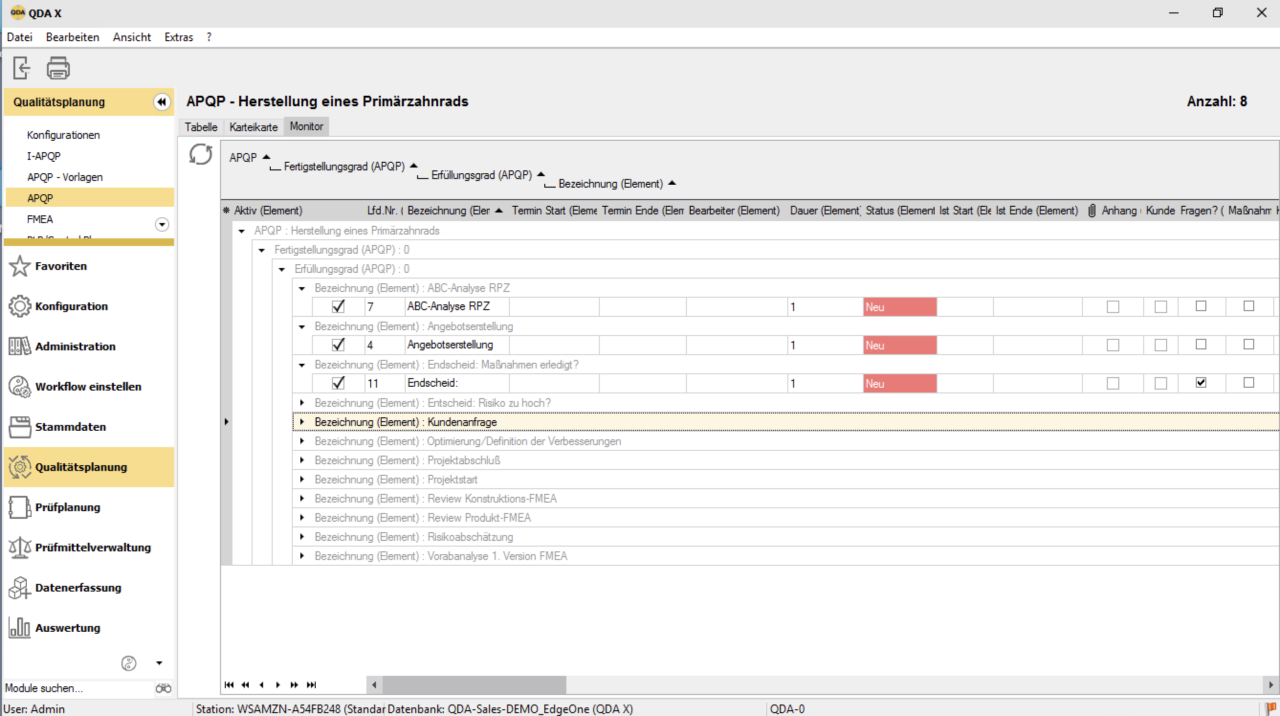

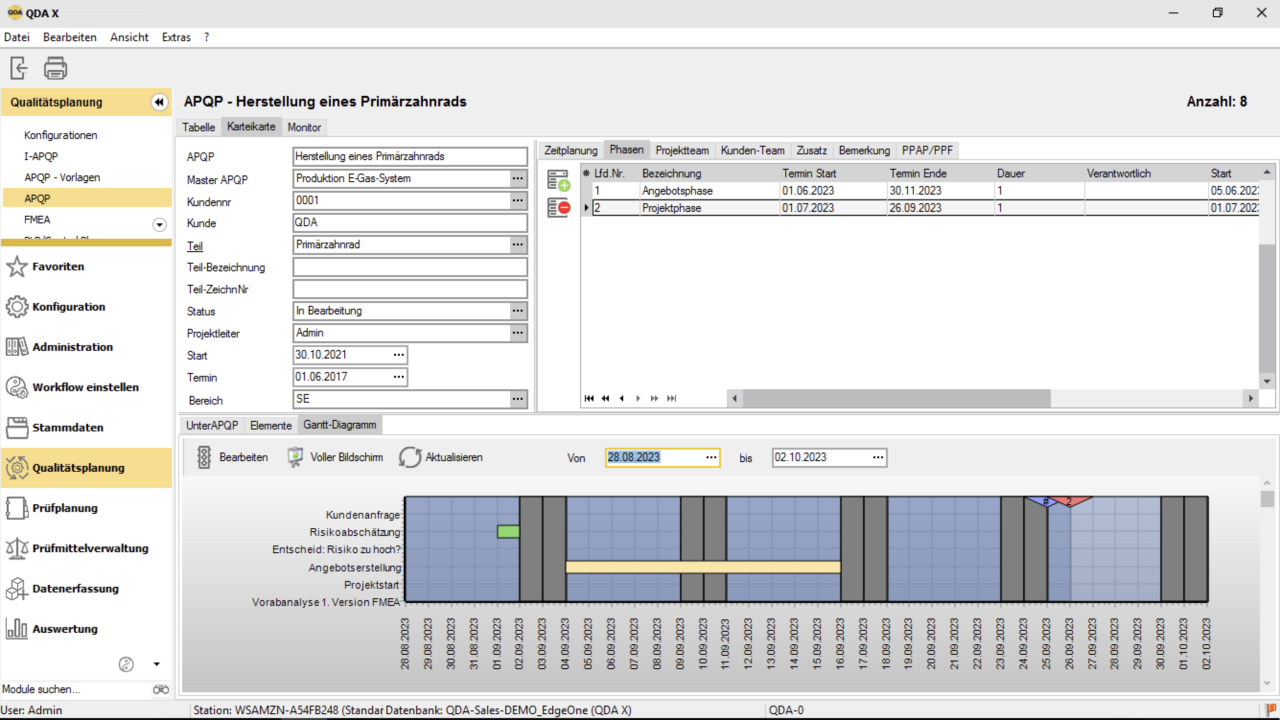

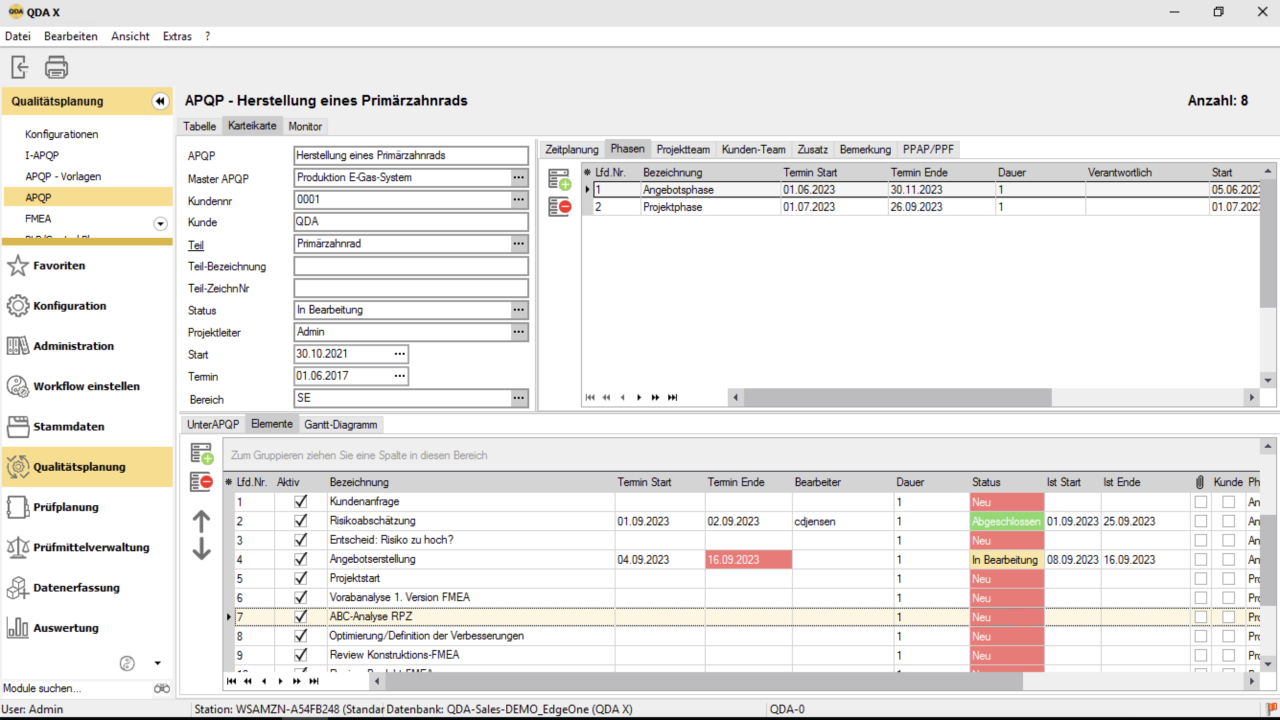

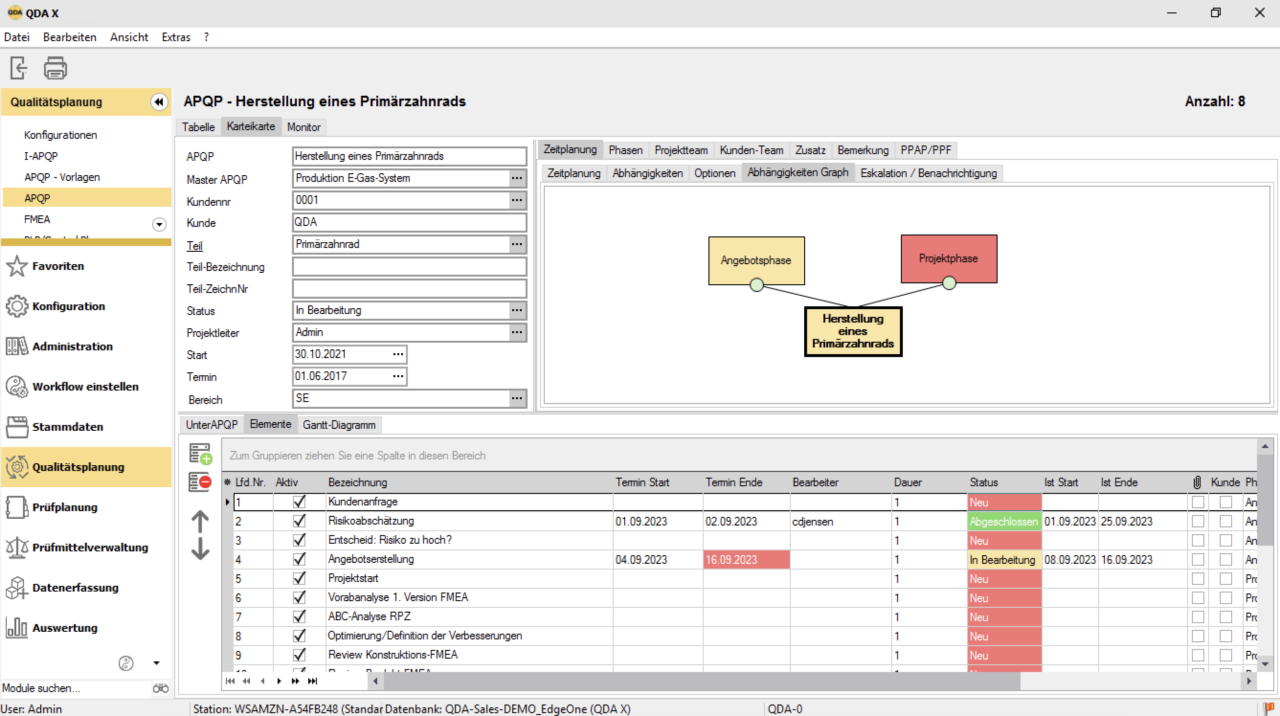

Functions of our APQP-Software

Easier handling of production and quality data

Our integrated quality management software gives you more insights into product documentation, enabling you to compile quality management reports and processes digitally. Without our software, these reports would otherwise have to be created manually for individual processes, leading to errors and intransparency. Likewise, data linking in terms of analyses is possible to obtain even more learnings.

Utilization of synergies through comprehensive quality management

Germanedge’s quality software solution uses part families. These consist of a group of parts that can be manufactured with similar machine tools, machining operations, fixtures and/or holding devices. When you reuse frequently used data in part families, you save time and minimize multiple entries of identical data. Our software efficiently and quickly exploits the synergies of integrated quality management.

The backbone of the APQP software is the storage and retrieval of the various documentation in a database

Compliance guidelines are usually interpreted very strictly. To comply with them, all changes to documents and forms must be cached and then made available on demand. Our software solution is compatible with all popular Microsoft applications and clearly displays the KPIs of your quality planning with one click. Data can thus be updated automatically, even if they come from different business areas. This means you can rely on reporting that is as fast as it is individual.

CIP (Continuous Improvement)

CIP plays a crucial role in the context of CAQ (Computer Aided Quality Management) in industrial production. CAQ is an approach that aims to monitor, control and improve the quality of products and processes in a company. CIP is a methodology that aims to promote continuous improvement in all aspects of a business, including quality and efficiency. The methodology is not new, but our software takes into account current developments:

- Digitalization and Industry 4.0: The trend towards digitalization in industry continues. Companies are increasingly starting to use IoT (Internet of Things) technologies and data analytics to monitor and improve production processes. This enables real-time data and better insights into production status.

- AI and machine learning: Artificial intelligence (AI) and machine learning are increasingly being used in quality control processes. These technologies enable automated defect detection, predictive maintenance and process optimization.

- Quality Management Software: The development of quality management software (QMS) progressed. Our QMS system provides comprehensive document management, training, risk management, and audit tracking capabilities, helping companies comply with quality standards and regulations.

- Lean Six Sigma: Lean Six Sigma remained an important approach to process improvement. Companies continued to use a combination of Lean methods to eliminate waste and Six Sigma techniques to reduce defects.

- Sustainability and environmental management: sustainability is gaining importance in the manufacturing industry. Companies are increasingly integrating environmental management practices into their CIP approaches to reduce waste, increase energy efficiency, and use environmentally friendly materials.

- Agile methods: Agile principles from software development are being applied to other areas, including manufacturing and quality management. Agile approaches enable more flexible and adaptable processes.

Integration of our APQP software

As a QDA user, you benefit from seamless integration of APQP into the overall quality management system. The software centralizes all information from planning, data collection and reporting. The production control plan can be transferred through this continuity above the partial release in the production.

The choice is yours: we install the software on-premise in your production environment and it is also available on all mobile devices via app or web browser. Likewise, the Germanedge database is included in the software, optionally usable on Amazon Workspace, Azure, Oracle, Citrix, Terminal Server. All you need is a login.

Our APQP software solution can be built modularly. This means that you have only one infrastructure, regardless of the number of modules used. The software architecture offers interfaces to PLM, CMM, ERP or MES systems. The software is also database driven, compatible with MSSQL, Oracle and PostgreSQL.

Step-by-step instructions on how to proceed if you are interested in the software:

- Contact us

- We show you the software via live demo

- We discuss requirements and technical integration with you

- We support you with integration and start

What is APQP-Software?

Definition

APQP (Advanced Product Quality Planning) software is a structured process to ensure that your products meet customer requirements. Because this method starts at an early stage of project management, cost-intensive errors do not occur in the first place.

The software is based on the cross-industry requirements for quality systems according to ISO 9001. In addition, IATF 16949:2016 describes more extensive requirements for series production in the automotive industry.

The requirements according to ISO 13485 also apply to companies that manufacture and market medical devices. Certification by a notified body is required to demonstrate the effectiveness of the QM software. When you use APQP software, you ensure effectiveness.

What tasks does APQP software perform?

APQP provides a standardized approach to product development and quality assurance. This facilitates collaboration between different departments and suppliers in project management.

Disadvantages for production without APQP?

If you don’t use APQP-Software, you risk not communicating changes to the product, process, operation, or regarding new policies in a timely manner, repeating errors, or failing to meet your customers’ requirements.

Advantages of using APQP?

The primary goal of using APQP software is prevention, you focus on customer satisfaction through the software and can detect changes early to define a suitable workflow. Through quality planning you can provide high quality products at low cost.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge