Fully integrated gauge management software: The cost-optimized way to standard-compliant measurement operation

Does your gauge management software synchronize with production? This way you increase the utilization of maintenance and maximize the availability of your measurement technology.

Measurement technology is expensive. This applies to test equipment, but especially to the supporting calibration technology. Therefore, it is clear: In order to test not only in compliance with standards, but also at optimal cost, you have to utilize the entire equipment to its full capacity.

However: In many places, the spectrum of measurement technology is too large to organize test equipment management with on-board resources. Instead, the planning, execution, monitoring, and documentation of maintenance work must be embedded in the CAQ system. Then gauge management can be networked with all other QM processes. For example, with statistical process control (SPC) or laboratory information management (LIMS).

Value creation and maintenance benefit from this in equal measure. While production has the necessary measuring equipment at its disposal at all times, the service department has the means to carry out its orders economically and to document them in an audit-proof manner. CAQ integration ensures that the necessary data exchange is automated. The same applies to workflow management between gauge managers and users.

Advantages of our gauge management software

Functions of our gauge management software

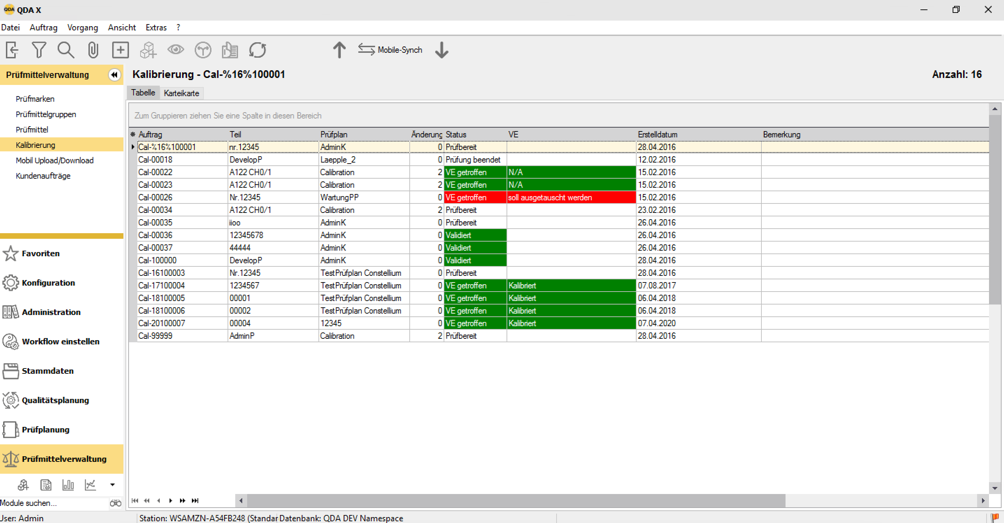

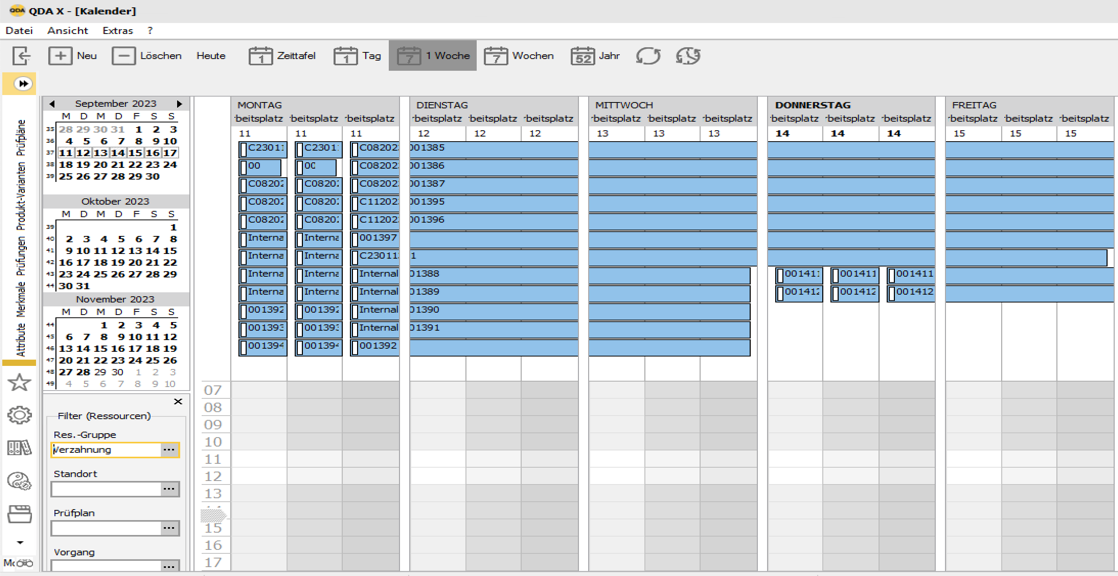

Create and monitor test plans

QDA gauge management organizes the entire planning process – from creating inspection plans and assigning them to calibration devices to performing and monitoring the individual maintenance steps.

Since gauge management is an integral part of our CAQ Suite, the plan specifications can be synchronized with the plans of the other CAQ modules. For example, with the order planning of Laboratory Information Management. This allows you to schedule the necessary maintenance orders in such a way that the availability of the actual value-added processes is maintained.

Group inspection plans can be used to group together measuring instruments with the same maintenance requirements. The associated inspection plan then only needs to be created once. The calibration characteristics described in it are automatically assigned to the grouped measuring instruments. Further labor savings are achieved by the fact that changes (e.g. after standard revisions) only have to be adjusted in the master plan.

Infinitely variable escalation processes

Our software monitors maintenance planning and ensures that all specifications are met in compliance with standards. Workflow management begins with notification of where and when which maintenance task is due. Since the monitoring of measuring equipment can address a wide variety of end devices, you can notify the colleagues affected by the maintenance measures in their productive systems.

In the event that measuring devices are not transferred in time, freely configurable alarms can be stored, which are also executed automatically. As a last resort, you can block overdue gauges for regular test operations. In addition, the gauge management system shows you exactly which gauges are currently being used where in the company. The serial numbers of the devices, which our CAQ reads out via the company network, provide information about this.

Flexible forms system

When a measuring device arrives for maintenance, the test equipment management informs the service technicians according to which standards the calibration has to be performed. The software provides the appropriate report templates for documenting this work.

If new inspection requirements arise, the service department can adapt or set up new forms on its own. For this purpose, our gauge management software provides a form editor that can be used without any programming knowledge. In this no-code editor, you can create all the necessary templates yourself in line with customer and standard requirements. In addition to the industry standards DIN EN ISO 9001, IATF 16949, ISO/IEC 17025 and MSA (measurement system analysis), we support the report formats MIL-STD-45662A and ISO 10012-1.

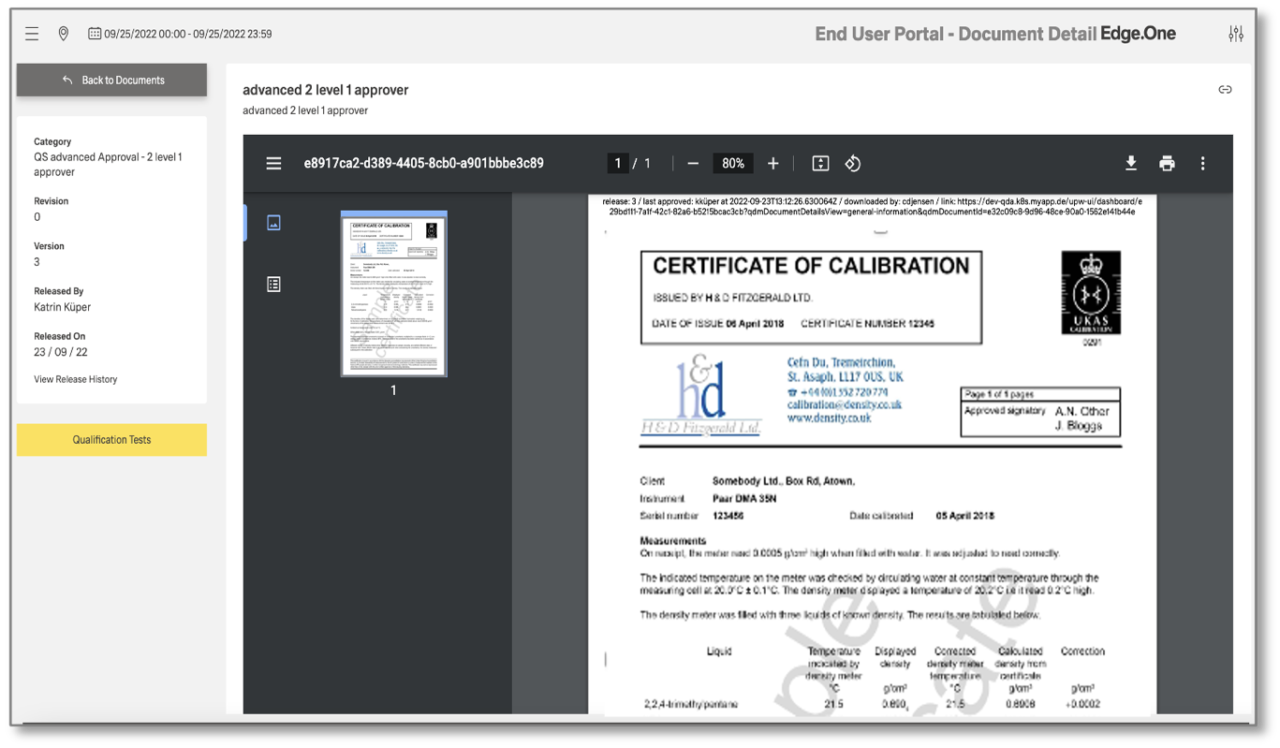

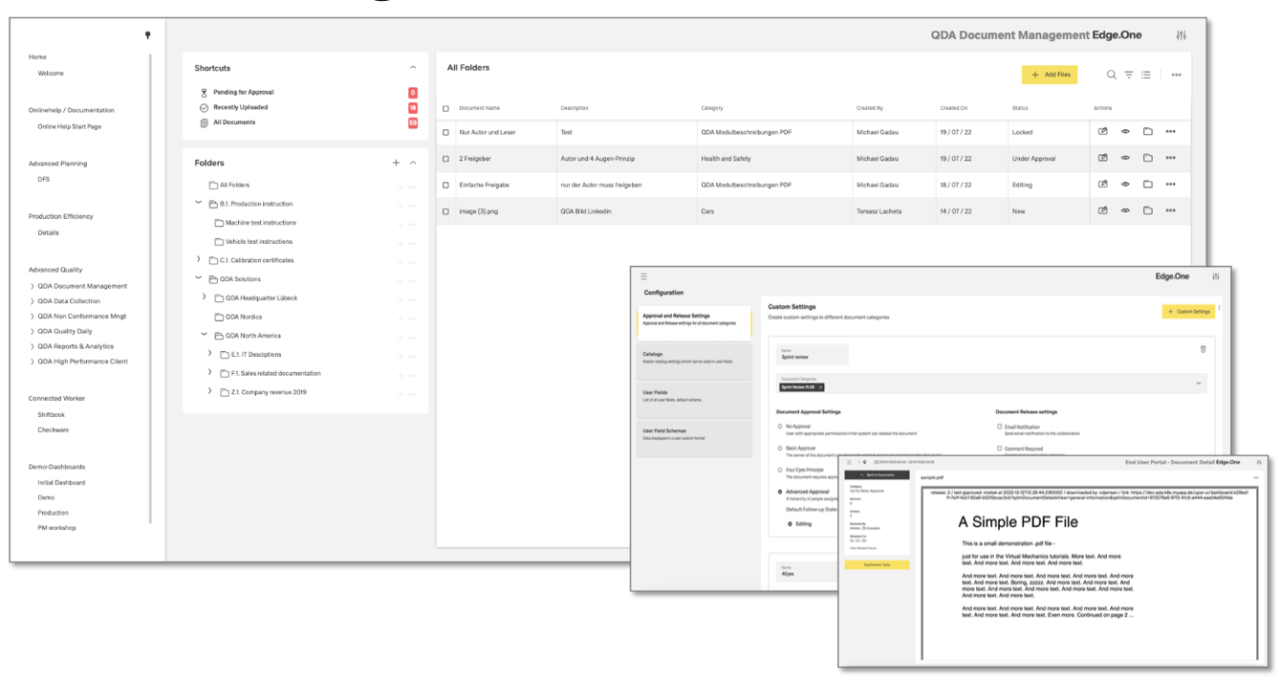

Traceability of all maintenance work

The test reports and certificates are stored in an audit-proof manner in the document management system QDA DMS. QDA DMS is also part of our CAQ suite. Through the interaction of gauge management and DMS, the maintenance history of each individual gauge can be traced without gaps. Against this background, you can prove the calibration status of the test equipment used for each individual measurement process.

In the event of a complaint, this helps to clarify possible quality deficits quickly and reliably. Complaint management is also part of our CAQ-Suite. This gives customer service direct access to the entire inspection history.

And: In addition to inspection reports, the DMS also manages work instructions that the service department must follow during calibration. Here, too, the complete change history of the documents can be searched at any time.

Ensure capability of your test equipment

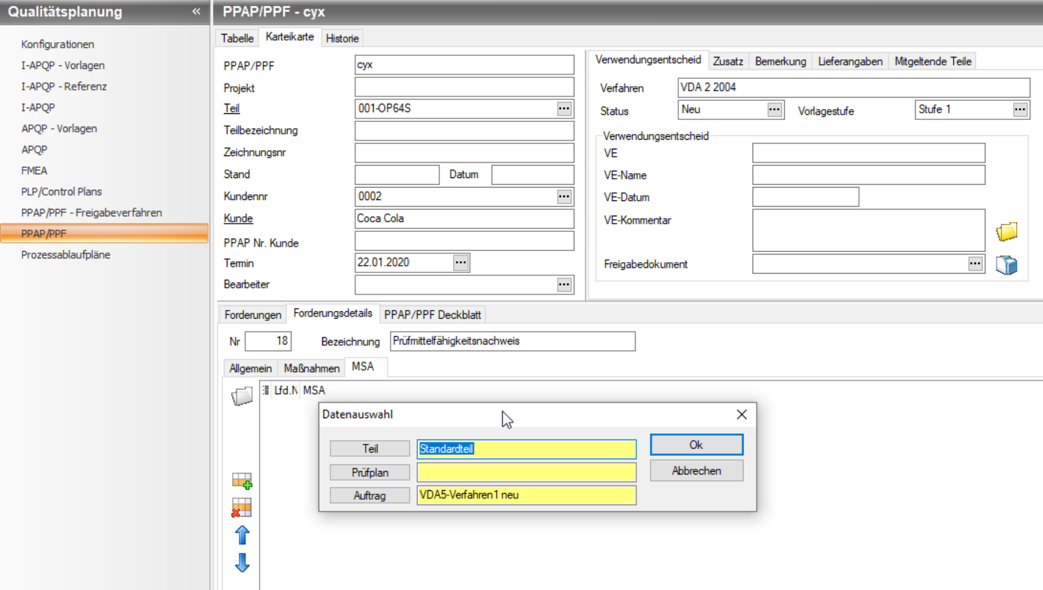

For the evaluation and improvement of your measuring systems, our gauge management offers a fully integrated measuring system analysis (MSA). The MSA provides you with reliable information on how accurate, correct and reproducible the measurements of your test equipment are. The aim is to ensure auditproof that all measuring systems are suitable for quality control without any restrictions. In addition, you receive information on where optimization measures are worthwhile or where they are necessary.

Our MSA covers the complete life cycle of your measurement systems. From commissioning and new installations to significant design changes and the replacement of influencing components in the course of repair or general overhaul.

Integration of the gauge management software

As soon as measuring devices are capable of transmitting their data electronically, you can integrate these devices into our gauge management software. As a result, all workflows can be organized that require the standard-compliant function of these measuring devices.

QDA gauge management is part of our CAQ suite. It has several hundred interfaces to integrate measuring instruments of any type quickly and cost-effectively. Especially older measuring technology can still be used.

You also have full freedom of choice in terms of infrastructure: You can use our software either on your own servers (on premise) or as a SaaS solution in the private, hybrid or public cloud. If you want maximum scalability, availability and data security, we recommend using technology-leading cloud hyperscalers such as Amazon, Azure, Google or the German provider Ionos. Additional security is provided by backups that our CAQ solution creates on-site at your company.

What is gauge management?

Definition

Gage management (PM) ensures the quality, reliability and functionality of measurement technology in industrial companies. As a sub-discipline of quality management (QM), PM ensures that all of a company’s measuring equipment operates in compliance with standards so that the various users can obtain audit-proof test results at all times.

What tasks does gauge management perform?

Test equipment management ensures that all test equipment is calibrated in accordance with standards. It carries out measurement system analyses (MSA) that prove the suitability of the measurement technology used and the test processes. In this context, the PM creates a suitable test plan and controls and documents the course of the individual maintenance steps.

What should a gauge management software be able to do?

GM software should have a platform-neutral architecture. Then a wide variety of measuring devices can be connected quickly and cost-effectively. In addition, it becomes possible to automate data exchange with the other QM disciplines that depend on functioning measurement technology. These include, for example, laboratory information management, complaints management and SPC.

Who benefits from the use of gauge management software?

Gauge managers and QM officers receive a fully integrated information system with which they can plan, control, monitor and document all PM processes. While the software independently executes the automatable steps of gauge management, the gauge managers can concentrate on handling deviations from the plan and processing new requirements (e.g. in the course of standard revisions).

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge